If you’re looking for the best bulldozer blades for heavy-duty earth moving in 2025, I recommend options made from high-quality materials like Nordic steel with around 500HB hardness, which resist wear and impact. They fit a variety of machinery, are easy to install, and guarantee durability even in tough conditions. Whether it’s weld-on or bolt-on, these blades enhance efficiency and longevity. Keep exploring, and you’ll find more details to help you pick the perfect setup.

Key Takeaways

- High-quality blades made from Nordic steel (~500HB) ensure maximum durability and wear resistance for demanding earth-moving tasks.

- Compatibility with various equipment types like skid steers, excavators, and bulldozers guarantees versatile heavy-duty application.

- Heavy-duty blades feature reinforced edges and optimal dimensions to enhance performance, lifespan, and operational efficiency.

- Installation options such as weld-on or bolt-on ensure secure attachment and safe, effective operation.

- Premium materials and surface treatments provide long-term value, reducing maintenance and replacement costs over time.

Mytee Products Weld-On Bucket Cutting Edge Blade (84x6x5/8)

If you’re looking for a durable and universal blade to upgrade your bucket’s performance, the Mytee Products Weld-On Bucket Cutting Edge Blade (84x6x5/8) is an excellent choice. Made from high-quality Nordic steel, it’s built for maximum wear, impact, and crack resistance, exceeding OEM standards with a hardness of around 500HB. Its design fits a variety of machinery like skid steers, excavators, and loaders, making it versatile. The blade’s excellent weldability simplifies installation, ensuring a secure attachment. Its increased length improves capacity, reduces side wear, and minimizes drag, making it a reliable, long-lasting upgrade for demanding heavy-duty applications.

Best For: Heavy-duty operators seeking a durable, universal bucket cutting edge blade to enhance equipment performance and lifespan.

Pros:

- Made from high-quality Nordic steel with approximately 500HB hardness for superior wear and impact resistance

- Universal fit compatible with various machinery such as skid steers, excavators, and loaders

- Excellent weldability ensures secure, hassle-free installation and long-lasting attachment

Cons:

- Made in Sweden, which may result in higher shipping costs for some regions

- Heavier and potentially more expensive than standard tempered steel blades

- Requires welding expertise for proper installation, which might necessitate professional assistance

Mytee Products Bucket Cutting Edge Blade (66 x 4 x 1/2)

The Mytee Products Bucket Cutting Edge Blade (66 x 4 x 1/2) stands out as an excellent choice for heavy machinery operators seeking a versatile, durable attachment. Its universal compatibility makes it suitable for excavators, loaders, and various buckets across construction, mining, and agriculture. Made from weather- and corrosion-resistant 30 Mn steel, it offers exceptional durability and abrasion resistance. The blade’s design enhances penetration and efficiency during digging and shoving tasks. With options for bolt-on or weld-on installation, it adapts easily to different equipment. Overall, this cutting edge provides reliable performance in demanding environments, ensuring long-lasting service and improved operational productivity.

Best For: heavy machinery operators in construction, mining, and agriculture seeking a durable, versatile cutting edge attachment for excavators and loaders.

Pros:

- Made from high-quality, weather- and corrosion-resistant 30 Mn steel for long-lasting durability.

- Universal compatibility with various heavy machinery and bucket types.

- Flexible installation options include bolt-on or weld-on, accommodating different operational needs.

Cons:

- Proper installation requires professional handling to ensure safety and effectiveness.

- Minor imperfections like uneven surfaces or slight dimension discrepancies may be present.

- No manufacturer warranty; users assume responsibility for safety and performance risks.

Bulldozer Blade Attachment for Skid Steer Loaders

For professionals seeking a reliable attachment that enhances their skid steer loader’s capabilities, the bulldozer blade attachment stands out as an essential tool. Made from high-quality steel, it’s built to withstand heavy-duty operations like soil pushing, ground leveling, and debris clearing. Its quick-attach design allows for fast, effortless setup, saving time and boosting productivity. Compatibility is key, so ensuring the link size matches—23.1 inches in length, 8.54 inches in height, and 14.17 inches in pitch—is vital for proper fit. Whether on construction sites or farms, this versatile attachment maximizes utility and durability in tough environments.

Best For: professionals in construction, farming, and land clearing seeking a durable, efficient bulldozer blade attachment for skid steer loaders.

Pros:

- Made from high-quality steel for exceptional durability and heavy-duty performance

- Quick-attach design allows for fast and easy installation, saving time

- Versatile for pushing soil, leveling ground, and clearing debris in various environments

Cons:

- Compatibility depends on matching specific link dimensions (23.1″ length, 8.54″ height, 14.17″ pitch)

- May require additional tools or equipment for installation on certain skid steer models

- Heavier construction could add to overall machine weight, affecting maneuverability in tight spaces

RC Skid Steer Loader Construction Truck 1/14 Remote Control Bulldozer with Lights

Designed for young construction enthusiasts and hobbyists, the RC Skid Steer Loader Construction Truck offers realistic operation with its 1:16 scale simulation and 360° rotation. At 1/14 scale, it mimics actual bulldozer movements, including adjustable functions like raising, lowering, and turning. Its lights add to the realism, making play more immersive. Operated via a 2.4GHz remote with a 30-40 meter control range, it allows multiple trucks to run simultaneously without interference. Weighing just over 4 pounds, it’s suitable for kids age 8 and up. This detailed, durable model provides hours of educational fun and a true construction experience.

Best For: young construction enthusiasts and hobbyists seeking a realistic, durable remote control bulldozer for educational fun and imaginative play.

Pros:

- Realistic 1:16 scale simulation with adjustable functions and lights for immersive experience.

- Long control range of 30-40 meters with anti-jamming technology allowing multiple units to operate simultaneously.

- Includes rechargeable batteries for extended playtime and easy swapping for continuous use.

Cons:

- Customer reviews average only 3.1 stars, indicating mixed satisfaction among users.

- Size and weight (over 4 pounds) may be cumbersome for younger children under age 8.

- Limited product ranking and reviews suggest it may have less visibility or user feedback compared to top-rated models.

Little People Replacement Part for Fisher-Price Construction Site Bulldozer Truck

If you have a Fisher-Price Little People Preschool Construction Site Bulldozer (Model # HPX89), this replacement part is an ideal choice to keep your child’s playtime going smoothly. It includes a yellow and gray bulldozer with a liftable blade, designed precisely for the original toy. Made by Fisher-Price, it guarantees a perfect fit and maintains the toy’s functionality. Compact at 3 x 2 x 0.75 inches and weighing just under 2 ounces, this sealed replacement helps restore play value for children aged 12 months to 5 years. It’s a reliable, genuine component that keeps the construction fun alive and well.

Best For: Parents and caregivers seeking authentic replacement parts to restore and extend the life of their Fisher-Price Little People Construction Site Bulldozer (Model # HPX89) for children aged 12 months to 5 years.

Pros:

- Genuine Fisher-Price replacement part ensures perfect compatibility and fit.

- Durable construction with a liftable blade enhances realistic play and interaction.

- Compact and lightweight design makes it easy to handle and store.

Cons:

- Limited to use with the specific Fisher-Price Little People Bulldozer HPX89 model.

- May be less appealing to children who prefer more interactive or electronic toys.

- Price may be higher compared to generic or third-party replacement parts.

Mytee Products Heavy Duty Bucket Cutting Edge Blade for Skid Steer and Excavator

The Mytee Products Heavy Duty Bucket Cutting Edge Blade stands out as an excellent choice for operators seeking maximum durability and wear resistance in tough conditions. Made from Nordic steel from Sweden, it features a hardness of around 500HB, twice that of typical carbon steel blades. This ensures superior crack resistance, impact strength, and long-lasting performance. Designed to fit skid steers, excavators, loaders, and bulldozers, it’s easy to weld and adds length to the bucket, reducing side wear and drag. Surpassing OEM standards, this blade delivers exceptional strength and extended service life, making it a reliable upgrade for heavy-duty earth-moving tasks.

Best For: heavy-duty operators and contractors seeking a durable, high-performance bucket edge for skid steers, excavators, and loaders.

Pros:

- Made from Nordic steel with 500HB hardness for superior wear and crack resistance

- Extends bucket lifespan by reducing side wear and drag during operation

- Easy to weld, ensuring a secure and reliable attachment in demanding environments

Cons:

- Heavier weight due to high-strength Nordic steel may require additional handling care

- Designed specifically for universal buckets, may not fit all custom or specialized equipment

- Higher cost compared to standard carbon steel blades due to premium materials and construction

Bush Hog Blade Pair CW

For those seeking a reliable and durable blade pair for rotary cutter applications, the Bush Hog Blade Pair CW stands out as a top choice. Made from high-quality steel, these blades are built to handle demanding cutting tasks and deliver consistent performance over time. With dimensions of 3 inches by 18-1/2 inches and a 1/2-inch thickness, they fit standard rotary cutters easily. Trustworthy and proudly made in the USA by Rancher Supply, these blades are designed for cutting grass, brush, and similar materials efficiently. Their durability and quality guarantee they’ll keep your equipment performing well through numerous projects.

Best For: homeowners, landscapers, and contractors seeking durable, high-quality blades for rotary cutters to efficiently mow grass and clear brush.

Pros:

- Made from high-quality steel for long-lasting durability

- Designed to fit standard rotary cutters easily

- Manufactured in the USA by a trusted brand, Rancher Supply

Cons:

- May require proper installation tools for secure mounting

- Not suitable for heavy-duty industrial cutting beyond standard use

- Dimensions are fixed; incompatible with non-standard rotary cutter models

WORKPRO Utility Knife Blades, SK5 Steel, 100-Pack with Dispenser

WORKPRO Utility Knife Blades, SK5 Steel, 100-Pack with Dispenser, stand out as an excellent choice for both DIY enthusiasts and professional contractors who need reliable, sharp blades at an affordable price. Made from high-quality SK5 steel with induction-hardened edges, these blades deliver long-lasting sharpness and durability. Their well-designed plastic dispenser offers safe, organized storage and easy access, with wall-mounting for added convenience. Suitable for cutting cardboard, plastic, rope, and more, these versatile blades are praised for their performance and value. Priced around $10, they provide an excellent cost-performance balance, making them a top pick for heavy-duty and everyday tasks.

Best For: DIY enthusiasts and professional contractors seeking reliable, sharp, and cost-effective utility blades for a variety of cutting tasks.

Pros:

- Made from high-quality SK5 steel with induction-hardened edges for long-lasting sharpness

- Comes with a well-designed, wall-mountable dispenser for safe, organized storage and easy access

- Versatile and compatible with most standard utility knives, suitable for a wide range of materials

Cons:

- Slightly thicker blades may reduce precision for delicate or razor-thin cuts

- Edge retention lasts about half as long as premium blades like Dewalt carbide or Lenox Gold

- The thickened blade design might not be ideal for extremely fine or detailed cutting tasks

OUTDOOR EDGE 3.5 RazorSafe Replacement Knife Blades, 6 Pieces

If you own a 3.5-inch RazorSafe Series knife and need reliable replacement blades, the OUTDOOR EDGE 3.5 RazorSafe Replacement Knife Blades are an excellent choice. This pack includes six razor-sharp blades made from durable Japanese 420J2 stainless steel, ensuring long-lasting sharpness. They’re compatible with models like Razor-Lite, Razor-Lite EDC, Razor-Pro, and Onyx-EDC, making replacements quick and easy. Please note, the blades are for replacement only, and the knife isn’t included. These blades are perfect for those who want dependable, high-quality replacements that maintain cutting performance during demanding tasks.

Best For: outdoor enthusiasts, hunters, and professionals who need reliable replacement blades for their 3.5-inch RazorSafe Series knives.

Pros:

- Made from durable Japanese 420J2 stainless steel for long-lasting sharpness

- Compatible with a variety of RazorSafe Series models for versatile use

- Comes in a pack of six blades, ensuring multiple replacements

Cons:

- Not compatible with 3.0-inch RazorSafe knives like ONYX-LITE (Model OX-30)

- Knife not included, only replacement blades are sold

- May require careful handling during replacement to avoid injury

Plastic Single Blunt Edge Dozer Blade 100 Pack

The Plastic Single Blunt Edge Dozer Blade 100 Pack stands out as an excellent choice for those seeking gentle, versatile cleaning tools. Made from flexible plastic, its blunt edge is perfect for removing stickers, decals, and latex paint drips without scratching surfaces. It fits standard #9 razor blade holders, making it easy to replace and use across various tasks. Whether you’re cleaning aquarium glass or delicate surfaces, this pack offers plenty of options for multiple projects. Its gentle design ensures safe, effective cleaning while minimizing damage. If you need a reliable, non-abrasive tool, this pack is a smart addition to your cleaning arsenal.

Best For: DIY enthusiasts, aquarium hobbyists, and anyone needing gentle, non-abrasive cleaning tools for delicate surfaces and stickers.

Pros:

- Made from flexible plastic for safe, gentle cleaning

- Compatible with standard #9 razor blade holders for easy replacement

- Suitable for cleaning multiple surfaces including glass and painted areas

Cons:

- May require more effort on stubborn adhesives or paint

- Not suitable for heavy-duty scraping or removing thick materials

- Plastic construction might wear out faster with frequent use

Oregon Precision Mower Blade Balancer

The Oregon Precision Mower Blade Balancer stands out as an essential tool for anyone who wants to maintain their mower’s performance and extend its lifespan. I’ve found it invaluable for verifying unbalanced or bent blades after sharpening, which helps reduce vibrations and ensures smoother cuts. It also prevents unnecessary wear on the engine and deck, boosting overall mower efficiency. Compatible with nearly all lawn mowers and rotary blades, it’s easy to use and highly durable thanks to its high-quality zinc die-casting. Made by Oregon experts, this reliable tool makes maintaining your mower simple, safe, and professional-grade.

Best For: homeowners, landscapers, and maintenance professionals seeking an easy-to-use, durable tool to ensure their mower blades are properly balanced for optimal performance and longevity.

Pros:

- Verifies unbalanced or bent blades post-sharpening to reduce vibrations and improve cut quality

- Compatible with almost all lawn mower makes, models, and rotary blades for versatile use

- Crafted from high-quality zinc die-casting for superior durability and long-lasting reliability

Cons:

- May require some initial familiarization to ensure proper balancing technique

- Not suitable for extremely small or specialized blades outside standard rotary mower types

- Slightly more expensive than plastic-based blade balancing tools, but offers greater durability

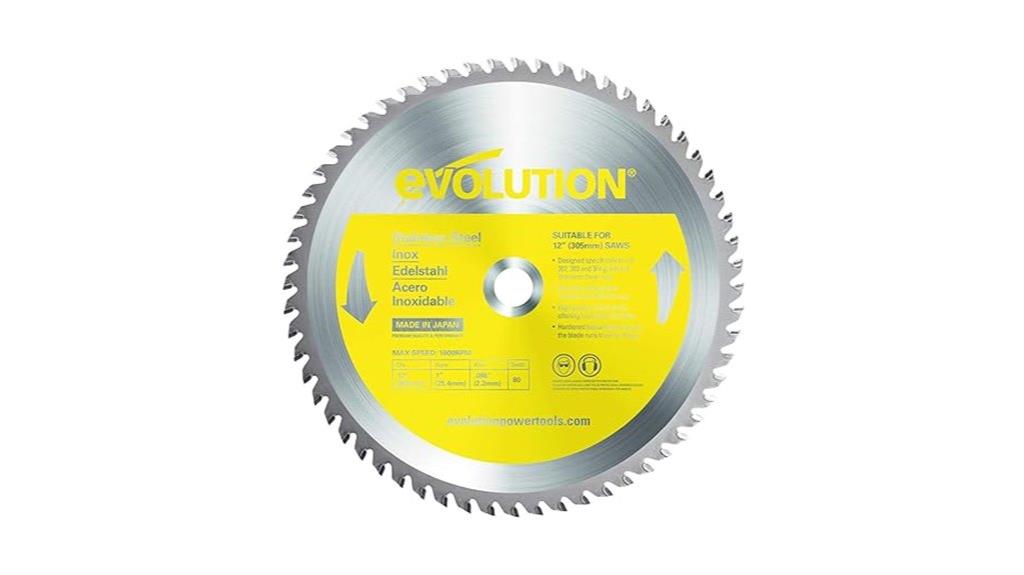

Evolution Power Tools 12-Inch 80-Tooth Steel Saw Blade

Designed for professional and serious DIY users, the Evolution Power Tools 12-Inch 80-Tooth Steel Saw Blade excels at delivering clean, precise cuts through stainless steel and other ferrous metals. With 80 carbide teeth and a .083-inch kerf, it’s optimized for low RPM saws like Evolution models, operating smoothly at 1600 RPM. Its dry cut technology minimizes heat, sparks, and burrs, ensuring high accuracy and minimal thermal damage. Although some users report carbide tip breakage after limited cuts, the blade provides excellent results on materials like stainless steel tubing, mild steel, and aluminum. Overall, it’s a reliable choice for clean, professional-grade cuts in demanding metalworking tasks.

Best For: professional fabricators and serious DIY enthusiasts seeking precise, clean cuts in stainless steel and ferrous metals with minimal heat and burr formation.

Pros:

- Delivers clean, precise cuts with minimal heat, sparks, and burrs

- Compatible with low RPM saws like Evolution models, ensuring smooth operation

- Produces smooth, flat, and straight cuts with high accuracy

Cons:

- Carbide tips may break after limited cuts, reducing lifespan

- Higher cost relative to its durability and lifespan

- Not suitable for saws over 1500 RPM, limiting versatility with some tools

PECHAM 24PCS Universal Oscillating Multitool Saw Blades

If you’re looking for versatile, durable blades that can handle a variety of cutting tasks, PECHAM’s 24-piece oscillating multitool saw set is an excellent choice. Made from high carbon and stainless steel, these blades resist corrosion, heat, and wear, ensuring long-lasting performance. The set offers seven different blade types, perfect for cutting wood, plastics, and metals, as well as scraping, sanding, and grout removal. Built-in measurement markers help with precise cuts, while universal compatibility means they fit many oscillating tools. Designed for ease of use, this kit provides quick blade changes, making it ideal for both professionals and DIY enthusiasts.

Best For: DIY enthusiasts and professionals seeking versatile, durable oscillating multitool blades for a wide range of cutting, scraping, and polishing tasks across different materials.

Pros:

- Made from high carbon and stainless steel for enhanced durability, corrosion resistance, and long-lasting performance

- Includes seven different blade types with built-in measurement markers for precise, versatile cutting applications

- Universal compatibility with many oscillating tools and quick-release design for easy blade changes

Cons:

- Not compatible with some popular models like Dremel MM40, MM45, or Bosch MX30

- May be too large or heavy for very delicate or intricate detailed work

- The electrophoretic black coating could wear over time with heavy use

Factors to Consider When Choosing a Bulldozer Blade

When selecting a bulldozer blade, I focus on several key factors to guarantee I get the right fit for my needs. I check the blade material quality, compatibility with my equipment, and the size and dimensions to match the job. Additionally, I consider durability, wear resistance, and the design of the cutting edge for peak performance.

Blade Material Quality

Choosing the right bulldozer blade material is essential because it directly affects the blade’s durability and performance. High-quality blades are made from tough steel alloys like hardened boron steel or Nordic steel, with a hardness around 500HB, offering excellent wear and crack resistance. The toughness of the material determines how well the blade withstands heavy impacts, abrasions, and extended use in demanding environments. Proper material selection also guarantees good weldability, which is crucial for secure attachment and longevity. Advanced steel alloys with through-hardening and impact-resistant properties notably extend the blade’s lifespan compared to lower-grade steels. By selecting high-impact, crack-resistant materials, you reduce the risk of deformation or failure during intense digging, pushing, or land clearing tasks, ultimately ensuring reliable, long-lasting performance.

Compatibility With Equipment

Selecting a bulldozer blade that fits your equipment properly is crucial for maximum performance and safety. You need to verify the blade’s dimensions—length, height, and pitch—match your machine’s specifications for a secure fit. Check the attachment method, whether weld-on or bolt-on, to confirm compatibility with your mounting system. It’s also important to confirm the mounting hole sizes and spacing align with your equipment’s connection points. The blade’s design—straight, curved, or blade-shaped front—should suit your operational needs and be compatible with your machine. Ultimately, review the manufacturer’s guidelines and specifications to ensure the blade is designed specifically for your make and model. Proper compatibility minimizes downtime and enhances efficiency in heavy-duty earth-moving tasks.

Blade Size and Dimensions

The size and dimensions of a bulldozer blade—such as length, height, and width—play a critical role in determining its effectiveness for specific tasks. Choosing the right size guarantees the blade can handle the required load without overburdening the machine or compromising maneuverability. Larger blades boost pushing power and material capacity but can make tight space navigation difficult. It’s essential to match the blade’s dimensions with your operational needs, whether grading, leveling, or pushing. Proper measurement helps prevent overloading, which can damage equipment and reduce safety. Compatibility with your bulldozer’s hydraulic system and attachment points is also key for secure, efficient operation. In short, selecting the correct blade size optimizes performance and safety in any earth-moving project.

Durability and Wear Resistance

Durability and wear resistance are essential factors when selecting a bulldozer blade, as they directly impact its lifespan and performance under demanding conditions. A high-quality steel, like Nordic or hardened boron steel, ensures the blade resists deformation and wear during heavy-duty work. The blade’s hardness, around 500HB, plays a crucial role in withstanding abrasive forces from soil, rocks, and debris, extending its service life. Surface treatments and specialized alloys further improve wear resistance by protecting against rapid material loss. Additionally, thicker blades and reinforced edges provide extra durability. Regular inspections and maintenance are vital for early detection of wear, helping to maximize the blade’s longevity and maintain peak performance throughout its operational life.

Cutting Edge Design

When choosing a bulldozer blade, the design of the cutting edge plays a essential role in its overall performance. A beveled or sharpened edge reduces resistance, boosting productivity by making material penetration easier. The material and hardness of the edge are critical for durability, helping it resist wear and chipping during tough operations. Reinforced weld zones in universal or adaptable designs ensure the edge withstands high-impact forces, extending its lifespan. Additionally, the shape and angle of the cutting edge should be tailored to specific tasks, such as digging, scraping, or cutting through dense materials. Proper design optimizes efficiency and minimizes downtime, making it a key factor in selecting the right blade for heavy-duty earth-moving tasks.

Attachment and Installation

Choosing the right attachment method for your bulldozer blade guarantees secure and efficient operation. First, verify that the blade is compatible with your skid steer or loader’s quick-attach or pin-on system, ensuring a proper fit. Check that the mounting hardware, like bolt hole diameter and pitch, matches your equipment’s specifications for smooth attachment. Decide between bolt-on or weld-on installation based on how permanent you want the setup to be and how easy removal should be. Make sure the blade’s dimensions and weight distribution support balanced mounting, promoting safe operation. Finally, follow the manufacturer’s instructions carefully during installation. Proper attachment not only guarantees safety but also extends the lifespan of your equipment and ensures ideal performance during heavy-duty earth-moving tasks.

Price and Value

Evaluating the price and value of a bulldozer blade requires balancing upfront costs with long-term benefits. I look at how the initial investment compares to durability, performance, and lifespan. Higher-priced blades often feature premium materials like Nordic steel, with a hardness around 500HB, which provides better wear and impact resistance. Cheaper options might save money initially but can lead to more frequent replacements, increasing overall costs. I also consider whether the blade’s features—such as weldability, size, and compatibility—justify its price relative to my specific needs. Striking the right balance between cost and quality helps minimize downtime and maintenance expenses over the blade’s operational life, ensuring I get the best value for my investment.

Frequently Asked Questions

How Do Different Blade Designs Impact Earth-Moving Efficiency?

Different blade designs considerably impact earth-moving efficiency by affecting how smoothly and quickly I can move material. For example, a straight blade offers precision for fine grading, while a U-blade handles larger loads better, increasing productivity. I find that choosing the right design depends on the project’s demands; a well-suited blade reduces effort, saves time, and enhances overall performance on tough terrain.

What Safety Precautions Are Necessary When Installing Bulldozer Blades?

Always wear proper safety gear, follow manufacturer instructions closely, and make certain the machine is on stable ground before installation. I double-check all connections, keep clear of pinch points, and use proper lifting techniques. I also communicate clearly with team members, turn off the engine when adjusting blades, and avoid working alone. Safety is my top priority to prevent accidents and ensure a smooth, secure installation process.

How Do Maintenance Routines Vary Between Blade Types?

I find that maintenance routines differ mainly based on blade type. For standard blades, I regularly check for wear, tighten bolts, and grease pivot points. For semi-universal or U-blades, I pay extra attention to hydraulic systems and cutting edges. Heavy-duty blades require more frequent inspections due to increased stress, ensuring all components are secure and lubricated. Tailoring maintenance to each blade type keeps my equipment running smoothly and prolongs its lifespan.

Can Blades Be Customized for Specific Terrain Conditions?

Yes, blades can definitely be customized for specific terrain conditions. I’ve seen manufacturers tailor blades with reinforced edges for rocky ground or wider blades for loose soil, ensuring better performance. Customization options include material upgrades, shape adjustments, and additional wear plates. When I need ideal results, I work with suppliers to modify blades, making sure they’re suited exactly to the terrain I’ll be working on, which boosts efficiency and durability.

What Are the Environmental Considerations When Selecting a Bulldozer Blade?

Imagine the earth as a delicate canvas—I need to choose a bulldozer blade that minimizes environmental impact. I consider factors like soil disturbance, vegetation preservation, and runoff control. Selecting eco-friendly blades with low ground pressure helps protect ecosystems and reduces emissions. I also evaluate how materials are sourced and recycled. By balancing performance with environmental responsibility, I guarantee my earth-moving tasks don’t leave a heavy footprint.

Conclusion

Choosing the right bulldozer blade is like selecting a trusted companion for your toughest journeys. Each option symbolizes strength, precision, and resilience—qualities essential for heavy-duty earth moving. As you pick your ideal blade, remember it’s more than just steel; it’s the key to turning your vision into reality. Trust in your choice, and let it carry your projects forward, forging paths through the toughest terrains like a steadfast anchor in a storm.