If you’re looking to boost your harvesting efficiency in 2025, I recommend exploring header attachments like the TM USWWAGOODS Header Lift Seal Kit for reliable sealing, the TM USWWAGOODS Replacement Lift Cylinder Seal Kit for John Deere models, the KUAFU Stack Pipe with Clamp for Farmall IH tractors, and the RAParts Elbow Exhaust fitting for international machinery. These options guarantee compatibility, durability, and easier maintenance. Stay with me to discover how each of these can maximize your farm’s productivity.

Key Takeaways

- Ensure compatibility with your harvester’s model and connection interfaces for seamless operation.

- Prioritize durable materials like stainless steel to withstand tough harvesting conditions.

- Choose attachments that are easy to install to minimize downtime and labor costs.

- Opt for reputable brands known for reliability, innovative features, and strong customer support.

- Consider cost-effectiveness, balancing price, durability, and performance for maximum efficiency.

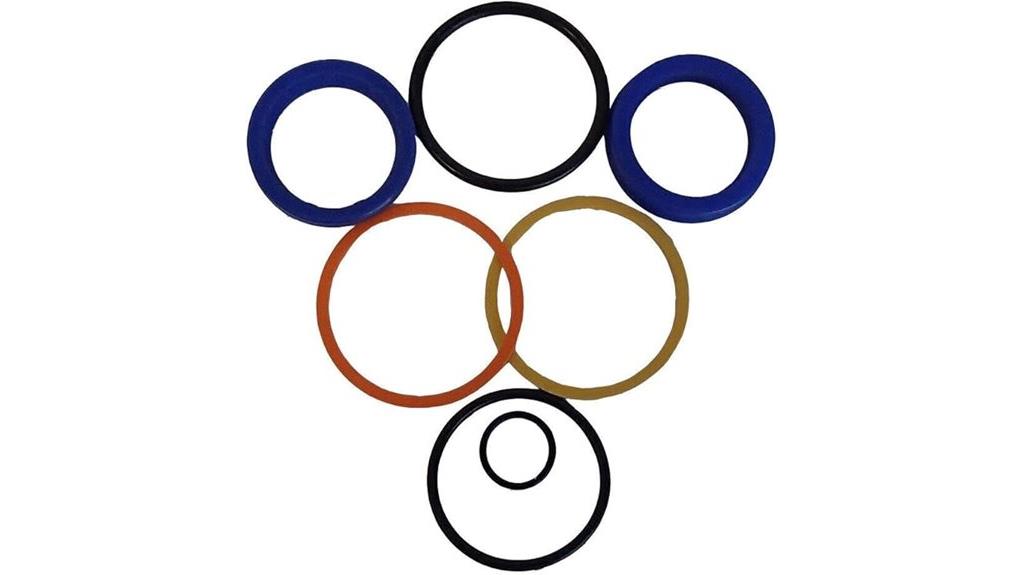

TM USWWAGOODS Replacement Header Lift Cylinder Seal Kit for John Deere Combine 3300 4400

If you’re looking to keep your John Deere Combine 3300 or 4400 running smoothly, the TM USWWAGOODS Replacement Header Lift Cylinder Seal Kit is a reliable choice. This kit replaces part numbers AH78774 and HYI40-1136, ensuring a perfect fit. It’s designed to enhance performance by sealing header lift cylinders, which helps improve fuel efficiency and reduce emissions. Compatible with various brands like Bad Boy, Briggs & Stratton, and Honda, it offers versatility for many agricultural machines. Manufactured by ASTRA-RelA-NBF-8704, this trusted brand ensures quality and durability. Installing this seal kit keeps your combine operating at peak performance, minimizing downtime and maintenance costs.

Best For: farmers and agricultural machinery operators seeking to maintain and enhance the performance of John Deere combines and compatible equipment.

Pros:

- Ensures a perfect fit for John Deere 3300 and 4400 models, reducing installation issues

- Improves fuel efficiency and reduces emissions, supporting eco-friendly operation

- Compatible with multiple brands and machinery, offering versatile application

Cons:

- May require professional installation for optimal results

- Availability is limited to specific models and compatible equipment

- Product warranty details need to be reviewed for coverage and service

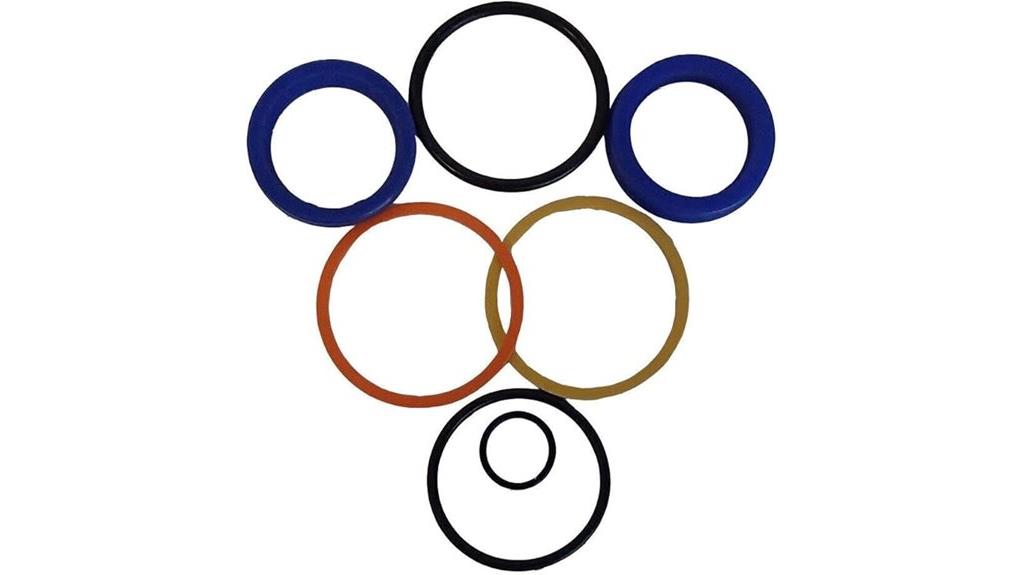

TM USWWAGOODS Header Lift Seal Kit for Allis Chalmers Combine (Fits 71188507-9)

For those operating Allis Chalmers combines, the TM USWWAGOODS Header Lift Seal Kit (Part Number: 71188507-9) offers a dependable replacement to keep header lift functions running smoothly. This kit fits models like L2, L3, and M3, ensuring reliable performance and proper operation. Manufactured by ASTRA-RelA, it meets high-quality standards and is compatible with various brands, including Bad Boy and Honda. With easy installation and a 30-day return guarantee, it’s a cost-effective solution to prevent leaks and maintain efficient header movement. Keeping your equipment in top shape has never been simpler with this trusted seal kit.

Best For: farmers and equipment operators who work with Allis Chalmers combines and need a reliable, easy-to-install header lift seal kit to ensure smooth header operation.

Pros:

- Compatible with multiple Allis Chalmers models (L2, L3, M3) for versatile use

- Manufactured by trusted brand ASTRA-RelA with high-quality standards

- Easy installation with a 30-day return guarantee for customer assurance

Cons:

- Limited to specific combine models; not suitable for other equipment

- May require technical knowledge for proper installation

- Availability might be seasonal or limited based on inventory

KUAFU Stack Pipe with Clamp for Farmall IH Tractors

The KUAFU Stack Pipe with Clamp is an ideal choice for Farmall IH tractor owners seeking to enhance their engine’s circulation and longevity. Made from durable 304 stainless steel, it’s designed specifically for models like the 1066, 1466, 1566, 1026, 1206, and 1256. The polished surface not only adds durability but also improves the tractor’s appearance. Easy to install with included clamps, it helps maintain peak engine performance by promoting better airflow. While professional installation is recommended for best results, this stack pipe ensures a long lifespan and reliable operation, making it a smart upgrade for your tractor’s engine system.

Best For: tractor owners with Farmall IH models like 1066, 1466, 1566, 1026, 1206, or 1256 seeking to improve engine airflow and longevity.

Pros:

- Made from high-quality 304 stainless steel for durability and corrosion resistance

- Easy to install with included clamps and accessories

- Enhances engine performance by promoting better airflow and circulation

Cons:

- Professional installation recommended for best results

- Instructions are not included, which may require additional research or expertise

- Available only through Amazon, limiting direct purchase options

RAParts 675316C2 Elbow Exhaust Fits International Harvester

RAParts 675316C2 Elbow Exhaust is an aftermarket replacement designed to fit specific International Harvester models, making it an ideal choice for farmers and equipment operators seeking sturdy and dependable exhaust components. This elbow exhaust fits models like the 1066, 1466, 1566, 4166, 4366, 4186, and 4386, guaranteeing compatibility across several popular tractors. Made to meet or surpass OEM standards, it offers durability and a solid fit. Replacing worn or damaged exhaust elbows with this part can help maintain peak engine performance and emission control. Always verify fit before ordering to ensure compatibility with your equipment.

Best For: farmers and equipment operators seeking durable, reliable exhaust components for International Harvester tractors.

Pros:

- Designed to meet or exceed OEM standards for quality and durability

- Compatible with multiple popular International Harvester tractor models

- Easy to install as a replacement part to maintain engine performance

Cons:

- Verification of fit required prior to purchase to ensure compatibility

- Some listings may use stock images; actual product appearance may vary

- As an aftermarket part, it may not have the exact original manufacturer finish

Factors to Consider When Choosing a Farm Harvester Header Attachment

When selecting a farm harvester header attachment, I always consider how well it will fit my existing equipment to avoid compatibility issues. I also look at durability and ease of installation to guarantee it can handle tough conditions without headaches. Finally, balancing cost and maintenance needs helps me choose an option that’s both affordable and reliable in the long run.

Compatibility With Equipment

Matching your header attachment with your specific farm harvester is essential to guarantee smooth installation and peak performance. I always start by verifying the compatibility of the attachment with my harvester’s make and model. Checking the part numbers or model codes ensures a proper fit and avoids costly mistakes. It’s also important to confirm that the mounting points and connection interfaces align perfectly with existing systems. I review manufacturer compatibility lists to confirm the attachment is designed for my brand and series. Sometimes, I need additional adaptors or accessories to secure a reliable connection. Taking these steps ensures the attachment integrates seamlessly, reducing downtime and maximizing efficiency during harvest. Proper compatibility is the foundation for a successful, trouble-free operation.

Material Durability

Choosing a header attachment with durable materials is essential because it directly impacts the equipment’s lifespan and reliability under tough field conditions. High-quality materials like stainless steel and reinforced composites provide superior resistance to corrosion, impact, and wear, which are common challenges during harvesting. Using heavy-duty materials helps the attachment withstand mechanical stresses, ensuring consistent performance across different crop types and environmental conditions. Investing in durable materials reduces the need for frequent replacements and lowers maintenance costs over time. The right choice of material also ensures the attachment maintains its integrity without degrading prematurely, even after prolonged use. Ultimately, selecting a durable material means fewer breakdowns, greater efficiency, and a longer-lasting harvest attachment that supports productivity throughout the season.

Easy Installation Process

A straightforward installation process can save you time and reduce frustration during setup. Look for attachments with clear instructions and minimal tools required, making the process smoother. Quick-connect fittings or snap-on components can greatly simplify attachment, especially if you’re not a technical expert. Pre-assembled headers with integrated mounting hardware eliminate the need for extra parts or adjustments, saving valuable time. Compatibility with standard mounting points ensures a hassle-free fit without modifications. Features like color-coded components or labeled parts can guide proper assembly, streamlining the entire process. Overall, choosing a header attachment designed for easy installation helps you get back to harvesting quickly and minimizes the effort needed to set up and secure your equipment efficiently.

Cost and Budget

When selecting a farm harvester header attachment, setting a clear budget is crucial to guarantee you get the best value for your money. I recommend establishing a budget range based on the total cost, including the attachment, installation, and future maintenance. Comparing prices from multiple suppliers helps ensure you’re getting a competitive rate. It’s also important to contemplate long-term value—look at durability and performance features relative to the price. Don’t forget to factor in additional costs like repairs or upgrades that might arise later. Keep an eye out for seasonal discounts, promotions, or bulk purchase deals, which can considerably reduce expenses. By planning carefully, you’ll make a smarter investment and maximize your efficiency without overspending.

Maintenance Requirements

Proper maintenance is key to keeping farm harvester header attachments running smoothly and avoiding costly breakdowns. Regularly inspecting and cleaning the headers helps prevent buildup, ensuring smooth operation and reducing mechanical failure risks. Lubricating moving parts and pivot points on a routine basis minimizes wear and extends the attachment’s lifespan. It’s also important to check seals and gaskets, replacing them when necessary to maintain proper sealing and prevent leaks that could impair performance. Monitoring for signs of corrosion or damage allows for timely repairs, avoiding expensive fixes and downtime. Following the manufacturer’s maintenance schedule and guidelines ensures all components function efficiently and reliably over time. Staying proactive with maintenance saves money and keeps your harvesting operations running at peak efficiency.

Brand Reputation

Ever wondered why some farm harvester header attachments perform better and last longer? It often comes down to brand reputation. Reputable brands consistently deliver high-quality products that perform reliably over time. They invest in research and development, which leads to innovative features that boost efficiency. Well-established brands also provide thorough customer support and warranties, giving peace of mind and long-term satisfaction. Their use of durable materials and adherence to strict safety and manufacturing standards ensure longevity and safety in demanding field conditions. Additionally, positive industry reviews and endorsements from other farmers serve as trustworthy indicators of a brand’s credibility. Choosing a recognized brand means you’re more likely to get a dependable, safe, and innovative attachment that meets your farm’s needs and stands the test of time.

Performance Efficiency

Choosing a farm harvester header attachment with essential performance efficiency is vital for maximizing your harvest output. Efficient headers boost crop collection by increasing cutting and gathering speeds, which shortens harvest time. High-performance headers feature advanced cutting mechanisms that stay consistent, even in tough or tangled crops. Selecting the right header can also improve fuel efficiency by reducing engine load and minimizing downtime. The design and condition of header components directly influence throughput; well-maintained parts prevent delays caused by malfunctions. Modern headers offer adjustable settings, allowing you to adapt to various crop types and field conditions. By prioritizing performance efficiency, you guarantee your equipment operates smoothly, saving time, fuel, and effort while maximizing yield potential during every harvest.

Frequently Asked Questions

How Do I Maintain Header Attachments for Longevity?

To keep your header attachments lasting longer, I recommend regular inspections for wear and tear, especially on blades and belts. Keep everything clean and lubricated to prevent rust and guarantee smooth operation. Tighten bolts and fasteners often, and replace damaged parts promptly. Storing attachments in a dry, sheltered area when not in use also helps prevent deterioration, extending their lifespan and maintaining peak performance during harvest season.

Are There Compatibility Issues With Older Combine Models?

Yes, older combine models can face compatibility issues with new header attachments, which is ironic because you’d think technology would be seamlessly integrated by now. I’ve learned that checking the compatibility specs before purchasing saves headaches later. Sometimes, adapting older equipment requires extra parts or modifications, so I always recommend consulting with manufacturers or specialists to guarantee a smooth fit. It’s better to be cautious than stuck with unusable gear.

What Safety Precautions Should I Follow During Installation?

When installing header attachments, I always make safety my top priority. I guarantee the equipment is turned off and disconnected from power sources before starting. I wear protective gear like gloves and safety glasses, and I work on a stable, level surface. I carefully follow the manufacturer’s instructions, double-check all connections, and use proper tools. Staying alert and taking my time helps prevent accidents and ensures a safe, successful installation.

Can Header Attachments Be Customized for Specific Crops?

Absolutely, header attachments can be adapted for specific crops. I’ve seen farmers tailor headers with different reel types, cutter bars, and augers to match crops like soybeans or wheat. Customization improves efficiency and reduces crop damage. I recommend discussing your crop needs with manufacturers—they often offer options or modifications. It’s a smart way to optimize harvest performance and ensure your equipment fits perfectly with your farming practices.

What Are the Signs of Wear Indicating Replacement Is Needed?

If you notice thinning or missing cutting blades, excessive vibration, or uneven feeding, it’s time to substitute your header attachment. I always check for rust, cracks, and worn-out guards regularly, as these signs can lead to poor harvest quality or equipment damage. Listening for unusual noises during operation also helps me catch wear early. Staying vigilant ensures I maintain maximum efficiency and avoid costly breakdowns in the field.

Conclusion

Choosing the right header attachment can transform your harvest season from good to great. Think of it as the secret ingredient that unlocks maximum efficiency—without it, you’re just missing out on potential gains. So, don’t settle for less; invest in the best, because in farming, precision and performance aren’t just goals—they’re the harvest you reap. Remember, the right tools turn hard work into harvest success—make sure yours are top-notch.