If you’re after the best front-end loader buckets for heavy-duty tasks in 2025, I recommend considering options like reinforced skid steer buckets, durable backhoe blades, bale spears, and versatile clamp-on hitches. These attachments are made from high-quality alloys and reinforced steel, ensuring longevity and performance. Compatibility and size are vital for safe operation, while features like quick-attach systems boost efficiency. Keep exploring to find the perfect fit for your demanding projects.

Key Takeaways

- Heavy-duty buckets made from high-strength steel and reinforced sidewalls ensure durability for demanding tasks.

- Compatibility with various loader models and quick-attach systems enhance versatility and ease of use.

- Features like reversible cutting edges and reinforced design improve performance and extend lifespan.

- Options include multifunctional buckets, grapple attachments, and dozer blades for diverse heavy-duty applications.

- Construction quality with corrosion-resistant coatings and high-tensile materials guarantees long-term reliability.

Front Loader Hay Bale Spear Attachment with 2 x 39 Bale Spears

If you’re looking for a reliable way to handle large hay bales, the Front Loader Hay Bale Spear Attachment with 2 x 39 Bale Spears is an excellent choice. It features two high-tensile, 39-inch forged spears that easily lift bales weighing up to 3000 lbs. The pre-assembled frame makes mounting quick and tool-free, wrapping around buckets up to 3/4 inch thick and 32 inches wide. Designed for durability and stability, it stays securely attached during transport. Whether on a farm or landscaping site, this attachment simplifies hay handling, minimizes downtime, and guarantees safe, efficient operations every time.

Best For: farmers, landscapers, and agricultural professionals handling large hay bales up to 3000 lbs with quick and secure attachment needs.

Pros:

- Easy, tool-free mounting with pre-assembled frame for quick setup and removal

- Heavy-duty forged spears designed for durability and secure grip on hay bales

- Compatible with buckets up to 3/4 inch thick and 32 inches wide, offering universal fitment

Cons:

- Weight of 112 lbs may require effort to install and handle during setup

- Not suitable for bales exceeding 3000 lbs or buckets smaller than specified dimensions

- Limited color or customization options as a standard attachment

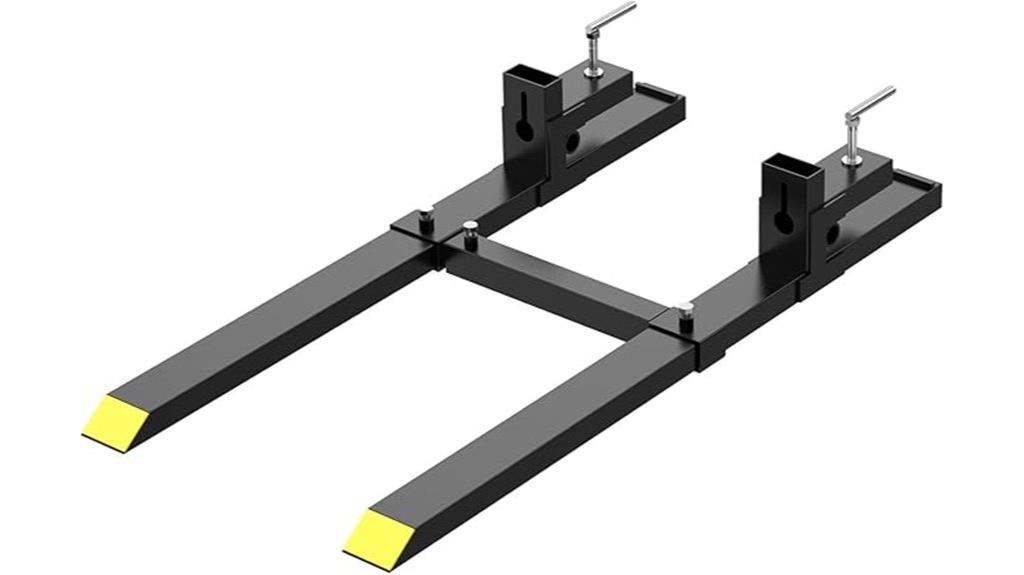

Pallet Forks for Tractor and Loader Attachments

Looking for a reliable set of pallet forks that can handle heavy-duty lifting tasks? These 60-inch forks, rated for 4,000 pounds, are perfect for tractor and loader attachments. Made from coated welded steel with T-shaped reinforcement, they’re built to last and resist deformation. The adjustable stabilizer bar, ranging from 18 to 34 inches, ensures stability during operation. Easy to install—just slide over the bucket’s edge and lock in place—they’re compatible with skid steer and front loaders. Despite a mixed customer review, users find them effective for hauling logs, hay, and debris. Overall, they’re a versatile, heavy-duty option for demanding lifting jobs.

Best For: those requiring durable, heavy-duty pallet forks for tractor or skid steer loader attachments to handle tasks like hauling logs, hay, and debris efficiently.

Pros:

- Constructed from coated welded steel with T-shaped reinforcement for durability and resistance to deformation

- Adjustable stabilizer bar (18 to 34 inches) enhances stability during lifting

- Easy to install by sliding over the bucket’s edge and locking securely

Cons:

- Customer reviews are mixed, with some reports of missing hardware upon delivery

- Weight of approximately 105.7 pounds may be cumbersome to handle during installation or transport

- No batteries required, but limited included components may require additional hardware for full setup

Titan Attachments Skid Steer Bucket Attachment V2 60 Reinforced

The Titan Attachments Skid Steer Bucket V2 60 Reinforced is an excellent choice for professionals and DIY enthusiasts seeking a durable, lightweight attachment that can handle demanding landscaping and construction tasks. Made from 1/8 structural steel with 1/2 thick sidewalls, it offers strength without excess weight. The 2 x 4 9-gauge tubular steel top support adds extra durability. Its universal skid steer connection makes it compatible with most brands, including Kubota, John Deere, and Ford. With a 60-inch width and ample capacity, it efficiently scoops and transports materials like dirt, mulch, and snow, boosting productivity on any project.

Best For: DIY enthusiasts and professionals seeking a durable, lightweight skid steer bucket for landscaping and construction tasks across various equipment brands.

Pros:

- Made from 1/8 structural steel with reinforced sidewalls for enhanced durability

- Universal skid steer connection compatible with multiple brands like Kubota, John Deere, and Ford

- Lightweight design maximizes loader capacity, reducing trips and increasing efficiency

Cons:

- May have limited capacity compared to larger or heavier-duty buckets

- Not suitable for extremely heavy or abrasive materials that require specialized buckets

- Slightly higher cost due to reinforced construction and quality materials

Clamp On Bucket Tractor Hitch 2 Receiver Fit for Deere Bobcat Loader

The Clamp On Bucket Tractor Hitch with a 2 Receiver Fit for Deere and Bobcat Loaders stands out for its universal compatibility, making it an ideal choice for tractor owners who need a quick and secure attachment solution. It easily slides onto the front bucket hitch receiver and locks in place with a simple handle turn, allowing for fast attachment and detachment within seconds. Built from heavy-duty steel and coated to prevent rust, it’s durable and reliable for various yard tasks, trailer hitches, or towing needs. Its design includes side baffles to prevent sliding during transport, ensuring stability and safety during use.

Best For: tractor owners needing a versatile, quick-attach hitch solution for Deere and Bobcat loaders for yard work, towing, and accessory attachment.

Pros:

- Universal compatibility with Deere and Bobcat front buckets

- Easy, tool-free installation and quick detachment in seconds

- Heavy-duty steel construction with rust-resistant coating for durability

Cons:

- May not fit specialized or non-standard bucket hitch receivers

- Requires manual locking, which may need secure handling during operation

- Not suitable for extremely heavy-duty industrial applications

Backhoe Front Loader Bucket Blade (118-7110)

If you’re replacing or upgrading a backhoe front loader bucket, the 118-7110 blade stands out with its durable heat-treated construction and reversible double bevel cutting edge, making it ideal for heavy-duty use. Designed to fit CAT 94 loader buckets, it measures 47.875 inches and requires two blades for a complete 94-inch edge. The blade features four 5/8-inch bolt holes spaced 12 inches apart, ensuring a secure fit. Its heat treatment enhances durability, while the reversible design allows for extended blade life. Proper verification of dimensions and bolt spacing is essential before installation to guarantee maximal performance and fit.

Best For: Heavy equipment operators and maintenance teams needing durable, reversible cutting edges for CAT 94 backhoe and front loader buckets.

Pros:

- Constructed with heat-treated steel for enhanced durability and longevity

- Reversible double bevel design allows for extended blade life and efficient cutting

- Fits many Caterpillar backhoe and front loader buckets with proper verification of dimensions

Cons:

- Requires two blades for a complete 94-inch bucket edge, potentially increasing costs

- Bolt hole spacing and dimensions must be carefully verified prior to purchase to ensure fit

- Shipping costs for returns or exchanges are at the buyer’s expense unless due to seller error

Mini Skid Steer Loader 4 in 1 Bucket

For contractors and DIY enthusiasts seeking maximum versatility, the Mini Skid Steer Loader 4-in-1 Bucket stands out as an ideal attachment. It fits most mini skid steer loaders with compatible link sizes, making installation quick and straightforward. This multifunctional bucket can serve as a traditional bucket, grapple, dozer blade, or clamp, streamlining tasks like digging, lifting, debris removal, and material handling. Built from heavy-duty alloys and steel, it’s designed for durability and long-term use. With hydraulic power and a compact size, it enhances productivity across various projects, offering a versatile solution that saves time and space on any job site.

Best For: contractors and DIY enthusiasts seeking a versatile, durable attachment to enhance productivity with mini skid steer loaders.

Pros:

- Multifunctional design allows use as a bucket, grapple, dozer blade, or clamp, increasing task versatility.

- Built from heavy-duty alloys and steel, ensuring long-lasting durability and resistance to deformation.

- Universal compatibility simplifies installation across most mini skid steer loaders, saving time and effort.

Cons:

- Heavy weight (500 pounds) may require additional effort for attachment handling and installation.

- Hydraulic-powered operation necessitates compatible hydraulic hoses and connections, potentially increasing setup complexity.

- Limited to models with specific link sizes, which may restrict compatibility with some skid steer loaders.

Mini Skid Steer Loader with Front Bucket

Looking to tackle tight spaces with ease? The Mini Skid Steer Loader with Front Bucket is perfect for narrow areas like orchards, farms, and construction sites. Its compact size—just over 2 meters long—makes maneuvering simple. Powered by a 13.5HP gas engine, it supports quick attachment swaps, including buckets, grapples, and forks. Triangular tracks provide excellent stability and anti-slip performance in tough environments. Features like foldable pedals, an intuitive control panel, and a front windshield cover make operation and maintenance straightforward. Its durability, versatile attachments, and rugged design guarantee reliable performance across landscaping, agricultural, and construction tasks.

Best For: professionals and contractors working in tight spaces such as orchards, farms, and construction sites who need a versatile, durable, and easy-to-maneuver compact loader.

Pros:

- Compact size facilitates easy maneuvering in narrow or confined areas.

- Supports quick attachment changes, increasing versatility for different tasks.

- Triangular tracks provide enhanced stability and anti-slip performance in tough environments.

Cons:

- Limited engine power may not be suitable for heavy-duty lifting or large-scale projects.

- Additional attachments come at an extra cost, increasing overall investment.

- The compact design might limit maximum lifting capacity compared to larger loaders.

Heavy-Duty Steel Bucket Tooth Bar for Tractor Loader

A heavy-duty steel bucket tooth bar is the ideal choice for tractor operators who need durability and reliable performance in tough conditions. I’ve found that these bars, made from alloy steel, offer exceptional toughness and resist rust thanks to their anti-corrosion coating. They’re easy to install with a bolt-on design, fitting bucket edges of 1/2 inch or less, and guarantee a secure, shake-free attachment. With six removable and interchangeable teeth, maintenance is straightforward and cost-effective. Whether excavating soil or tackling urban construction, this attachment enhances your tractor’s efficiency and longevity, making it a must-have for heavy-duty tasks.

Best For: tractor operators and construction professionals seeking durable, easy-to-maintain bucket attachments for heavy-duty excavation and urban projects.

Pros:

- Made from high-quality alloy steel for superior toughness and durability

- Easy bolt-on installation without drilling, fitting most loader types

- Removable and interchangeable teeth for cost-effective maintenance

Cons:

- Fits only bucket edges of 1/2 inch or less, limiting compatibility with larger buckets

- May require specific tools for installation or replacement of teeth

- Heavy-duty design might be more cumbersome to handle during initial setup

RAParts D129256 Lower Pin Fits Case Bucket 580K & 580SK Backhoe Loader

The RAParts D129256 Lower Pin is an essential replacement part designed specifically for Case backhoe loaders like the 580K, 580SK, and 590 models. This aftermarket component guarantees the secure attachment of the bucket to your machine, maintaining peak performance. It’s a direct replacement for OEM parts such as 177272A1 and D129256, but you should verify fit before ordering. Made to withstand heavy-duty use, this lower pin helps keep your backhoe loader operating smoothly and safely. Whether you’re maintaining or repairing, this durable pin is a crucial part of your equipment’s longevity and efficiency.

Best For: contractors, equipment maintenance professionals, and operators needing reliable replacement parts for Case backhoe loaders like the 580K, 580SK, and 590 models.

Pros:

- Designed as a direct aftermarket replacement for OEM part numbers, ensuring compatibility.

- Made from durable materials to withstand heavy-duty use and extend equipment lifespan.

- Easy to install with verified fit, helping to reduce downtime during repairs.

Cons:

- Compatibility verification required before purchase to ensure proper fit.

- Some listings may use stock images, so actual product appearance could differ.

- As an aftermarket part, it may not include the same warranties or guarantees as OEM components.

Backhoe Front Loader Bucket Blade 44.5 for CAT 88 Loader

If you’re operating a CAT 88 Loader and need a durable replacement blade, the Backhoe Front Loader Bucket Blade 44.5 offers a reliable solution. This 44.5-inch blade, model 9W-8215, is made from wear parts and G.E.T., ensuring it withstands heavy-duty use. It fits various Caterpillar backhoe and front loader buckets, but you should verify dimensions and bolt hole spacing before purchasing. The blade measures 3/4 inch thick, 8 inches high, and nearly 44.5 inches long. Its sturdy construction and compatibility make it an excellent choice for maintaining peak performance and extending your equipment’s service life.

Best For: contractors, heavy equipment operators, and maintenance crews seeking durable replacement blades for CAT 88 loaders and compatible backhoe/front loader buckets.

Pros:

- Made from wear parts and G.E.T. for enhanced durability and long service life

- Precisely sized at 44.5 inches to fit CAT 88 loader buckets and many other Caterpillar models

- Easy to install with verified bolt hole spacing, ensuring compatibility and quick replacement

Cons:

- Color may vary, which could affect visual match with existing equipment

- Compatibility depends on verifying dimensions and bolt hole spacing; incorrect fitment may require returns or modifications

- Heavy-duty construction may be heavier than OEM blades, affecting handling during installation

Titan Attachments Skeleton Rock Bucket for John Deere Loader

Designed specifically for John Deere loaders with hook and pin systems, the Titan Attachments Skeleton Rock Bucket offers unmatched durability and versatility. Crafted from grade 50 structural steel, it features 0.5-inch thick sidewalls and a sturdy 4×4 9-gauge tubular steel top support, ensuring long-lasting strength. With a 72-inch width and a low-profile design, it’s perfect for sifting rocks, debris, snow, and mulch. The replaceable teeth make maintenance easy, while its compatibility spans numerous John Deere models across series. Weighing 650 pounds, it’s built for heavy-duty tasks, making your excavation, landscaping, or debris removal projects more efficient and reliable.

Best For: contractors, landscapers, and equipment operators seeking a durable, versatile skeleton rock bucket for efficient debris, rock, and material handling with John Deere loaders.

Pros:

- Constructed from high-grade grade 50 structural steel for exceptional durability.

- Compatible with a wide range of John Deere loader models across multiple series.

- Features replaceable teeth for easy maintenance and extended lifespan.

Cons:

- Heavy at 650 pounds, which may require additional lifting capacity.

- Designed specifically for hook and pin systems, limiting compatibility with other attachment types.

- May be overbuilt for lighter duty tasks, potentially increasing operational costs for small jobs.

Mytee Products 8′ Backhoe Bucket for Excavator Attachments

For those seeking a durable and versatile attachment, the Mytee Products 8′ Backhoe Bucket stands out with its compatibility for excavators and skid steers, making it ideal for heavy-duty digging and excavation tasks. Made from alloy steel with a powder-coated black finish, it’s built to resist corrosion and withstand tough conditions. The bucket features drainage holes to prevent water buildup, and its bolt-on carbon steel teeth enhance durability. At just 72 pounds, it’s lightweight yet robust, fitting mini excavators and skid steers easily. Rated 4.6 stars, it’s a reliable choice for demanding projects, though some users may need modifications for perfect fit.

Best For: contractors and DIY enthusiasts seeking a durable, versatile backhoe bucket compatible with mini excavators and skid steers for heavy-duty digging tasks.

Pros:

- Constructed from alloy steel with corrosion-resistant powder coating for long-lasting durability

- Includes bolt-on carbon steel teeth for enhanced excavation performance

- Lightweight at 72 pounds, making it easy to handle and install on compatible equipment

Cons:

- Some users may need to modify or weld for proper fit on certain backhoe models

- Limited size (8′ width), which may not suit larger excavation projects

- Compatibility issues reported with specific backhoe attachments, requiring adjustments

KUAFU Tractor Bucket Protectors (2 Pcs)

KUAFU Tractor Bucket Protectors are an excellent choice for anyone looking to safeguard their tractor buckets during tough tasks like snow removal or gravel spreading. These protectors fit loaders perfectly and help prevent damage to driveways, yards, and farms. Made of heavy steel, they’re built for durability and can withstand harsh weather, resisting deformation and corrosion thanks to a powder-coated finish. The upgraded handle and double lock nuts ensure secure, reliable installation. Bright orange color enhances visibility, and green options match various vehicles. Each pack includes two protectors with mounting hardware, making them a practical, protective addition to keep your buckets in top shape.

Best For: tractor owners and operators seeking durable bucket protection during snow removal, gravel spreading, or similar tough tasks.

Pros:

- Made of heavy steel for high strength and long-lasting durability

- Resistant to harsh weather, deformation, and corrosion due to powder coating

- Bright orange color enhances visibility for safety and ease of use

Cons:

- No installation instructions included, requiring professional installation

- Installation requires screws, which may need additional tools or hardware

- Limited color options (primarily orange and green) may not match all vehicle aesthetics

Titan Attachments Skid Steer 12 Bucket and Thumb Attachment

If you’re looking for a versatile attachment that handles small to medium digging tasks in tight spaces, the Titan Attachments Skid Steer 12 Bucket and Thumb is a solid choice. It features a universal skid steer hookup, a 14-inch bucket, and a bolt-on backhoe thumb for added functionality. Made from durable tube steel, it offers superior strength and longevity. Weighing 517 pounds, it’s designed for easy maintenance with greaseable pins and bushings. However, some users report hydraulic leaks and limited warranty support, so it’s wise to contemplate customer feedback before purchasing. Overall, it’s a capable option with some reliability concerns.

Best For: homeowners and small contractors needing a durable, versatile skid steer attachment for small to medium digging tasks in confined spaces.

Pros:

- Made from durable tube steel for superior strength and longevity

- Features a universal skid steer hookup compatible with various models

- Includes greaseable pins and bushings for easier maintenance

Cons:

- Reports of hydraulic cylinder leaks shortly after installation

- Limited warranty support and difficulty obtaining service from manufacturer

- Mixed customer reviews with some experiencing hydraulic failures and poor customer assistance

Factors to Consider When Choosing a Front‑End Loader Bucket

When selecting a front-end loader bucket, I focus on factors like material durability, compatibility with my equipment, and the right size for the job. I also consider how versatile the attachments are and how easy it will be to maintain or replace parts. These points help guarantee I choose a bucket that performs reliably and fits my specific needs.

Material Durability and Strength

Choosing a front-end loader bucket with the right material is essential for ensuring it can handle heavy loads without bending or breaking. High-strength or alloy steel is ideal because it offers the necessary resistance to deformation under demanding conditions. Reinforced sidewalls and thick cutting edges, usually between half to three-quarters of an inch, substantially boost durability and extend the lifespan of the bucket. Heat-treated and reversible cutting edges improve wear resistance, simplifying maintenance and reducing downtime. Protective coatings, such as anti-rust or anti-corrosion finishes, shield the bucket from environmental damage, especially in harsh climates. The construction quality, including welded joints and reinforced structural components, directly influences the overall strength and longevity, ensuring the bucket performs reliably over time.

Compatibility With Equipment

Selecting a front-end loader bucket that fits your equipment requires careful attention to compatibility details. First, check that the connection type matches your attachment system, whether it’s skid steer quick-attach or hook-and-pin. Next, verify that the bucket’s width and height align with your loader’s dimensions and capacity restrictions to ensure safe operation. Confirm that the mounting hardware and bolt hole spacing are compatible with your loader’s specifications for a secure fit. It’s also important to verify the bucket’s load capacity and weight don’t exceed your equipment’s rated limits, preventing overstressing your machine. Finally, review manufacturer charts and specifications specific to your loader model and brand. Proper compatibility guarantees safe, efficient performance and prevents costly mismatches.

Bucket Size and Capacity

Matching the bucket size to your loader’s capacity is essential for safe and productive operation. Choosing a bucket with the right volume guarantees you can handle the workload efficiently without overloading the machine. Larger buckets increase productivity by allowing more material per load but can reduce maneuverability and put extra strain on the engine and hydraulics. It’s also important to match the bucket width to your loader’s lifting arms and working environment, optimizing loading and unloading. Consider the material type—heavier or bulkier materials need a smaller, more robust bucket to prevent damage and overloading. By selecting an appropriately sized bucket, you balance efficiency, safety, and equipment longevity, leading to better performance and fewer operational issues.

Versatility of Attachments

The versatility of front-end loader attachments substantially expands what you can accomplish with a single machine. Interchangeable attachments like buckets, forks, or blades let you tackle a variety of tasks without switching equipment. Multi-functional options, such as 4-in-1 buckets, enable digging, grabbing, dozing, or clamping with one attachment, saving time and effort. Compatibility is key, so choosing a loader with a universal or adaptable mounting system ensures you can easily swap attachments as needed. Features like replaceable teeth or reversible cutting edges add customization for different workloads, extending the lifespan of your equipment. Quick-attach mechanisms further streamline the process, minimizing downtime and boosting productivity. Overall, selecting versatile attachments enhances your loader’s capabilities and maximizes operational efficiency in diverse applications.

Maintenance and Replacement Ease

When choosing a front-end loader bucket, prioritizing ease of maintenance and replacement can save you time and reduce costs. I look for attachments with removable, interchangeable teeth or cutting edges—these make repairs straightforward and cheaper. Easy access to components like pins, bushings, and hydraulic hoses is vital; it speeds up inspections and repairs. I prefer models with reinforced structures and durable materials, as they resist wear and extend intervals between maintenance. Straightforward installation and disassembly procedures help minimize downtime during part replacements. Additionally, I value equipment that features clear visual indicators or diagnostic tools, which alert me to early signs of wear or damage. These features guarantee I can maintain peak performance without unnecessary delays or expenses.

Price and Budget Constraints

How do you guarantee you get the best value when selecting a front-end loader bucket within your budget? First, establish a clear price range to narrow your options and prevent overspending. Don’t forget to factor in the cost of any necessary features or accessories for your specific tasks, as they can add up. It’s vital to balance price with quality—choosing a bucket that offers durability and performance without sacrificing key features. Think long-term; consider maintenance costs and the lifespan of the bucket to ensure you’re making a smart investment. Be aware of hidden costs like shipping, installation, or compatibility fees, which can unexpectedly inflate your overall budget. By carefully evaluating these factors, you’ll find the best bucket that fits both your needs and your financial plan.

Frequently Asked Questions

What Materials Are Best for Heavy-Duty Loader Buckets?

I recommend using high-strength steel alloys for heavy-duty loader buckets because they offer excellent durability and resistance to wear under tough conditions. Hardox steel and other abrasion-resistant materials are ideal, as they can withstand constant impact and abrasion without compromising performance. Additionally, composite materials are emerging as lightweight options, but steel remains the top choice for maximum strength and longevity in demanding applications.

How Do Bucket Weight Impacts Machine Performance?

Bucket weight critically impacts machine performance; heavier buckets add stability but can slow down movement and increase fuel consumption. Lighter buckets boost agility and reduce strain on the loader, enhancing efficiency. I find balancing weight is vital—too heavy hampers handling, too light risks durability. By choosing the right weight, I guarantee my loader performs ideally, providing powerful productivity without sacrificing speed or safety.

Are There Eco-Friendly Options for Heavy-Duty Buckets?

Yes, there are eco-friendly options for heavy-duty buckets. I’ve seen manufacturers develop models using recycled materials or sustainably sourced composites that reduce environmental impact. These buckets maintain durability and performance, so you don’t have to sacrifice power for eco-consciousness. If you’re looking to lessen your carbon footprint while handling tough jobs, I recommend exploring these greener options—they’re innovative, sustainable, and built to last.

How Does Bucket Design Influence Digging Efficiency?

Think of bucket design as a finely tuned instrument, shaping digging efficiency like a master musician crafting sound. A well-designed bucket reduces resistance, improves load capacity, and speeds up operation. Features like curved edges and reinforced lips cut through material smoothly, while optimized weight distribution prevents unnecessary strain. By paying attention to these details, I find that my digging becomes quicker, easier, and more effective, just like a symphony hitting perfect notes.

Can Aftermarket Attachments Improve Bucket Lifespan?

Absolutely, aftermarket attachments can markedly improve a bucket’s lifespan. I’ve seen how adding wear plates, edge protectors, and advanced liners reduces damage from heavy-duty tasks. These upgrades absorb impact and resist abrasion, extending the bucket’s operational life. Investing in quality aftermarket components not only boosts durability but also minimizes downtime and repair costs, making them a smart choice for anyone aiming to get the most out of their front-end loader.

Conclusion

So there you have it—14 front-end loader buckets that promise heavy-duty performance in 2025. Because clearly, the world needs more buckets to carry everything from hay to heartbreak. Remember, choosing the right bucket isn’t just about specs; it’s about avoiding those embarrassing moments when your loader can’t handle what you throw at it. Happy lifting, and may your buckets never let you down—unless, of course, they’re the wrong ones!