When choosing the best grain augers for 2025, I focus on models with durable construction, corrosion-resistant coatings, and compatible sizes for your equipment, like those from RAParts and TECHTONGDA. Efficient, reinforced, and easy-to-maintain augers can boost your harvest speed and longevity. Whether you need portable conveyors or heavy-duty loading augers, there are top options that fit various needs. Stick around, and I’ll guide you through the key picks and factors to examine.

Key Takeaways

- Top grain augers feature durable, abrasion-resistant steel and reinforced joints for long-lasting performance during demanding harvests.

- Compatibility with major combine models like John Deere 8820 and Case-IH ensures proper fit and efficient operation.

- High-capacity conveyors process grains quickly, significantly improving loading and unloading efficiency in large-scale farming.

- Easy installation, modular design, and low maintenance requirements make these augers suitable for both professional and DIY users.

- Expert-reviewed picks focus on reliability, performance, and cost-effectiveness, ensuring optimal harvest productivity in 2025.

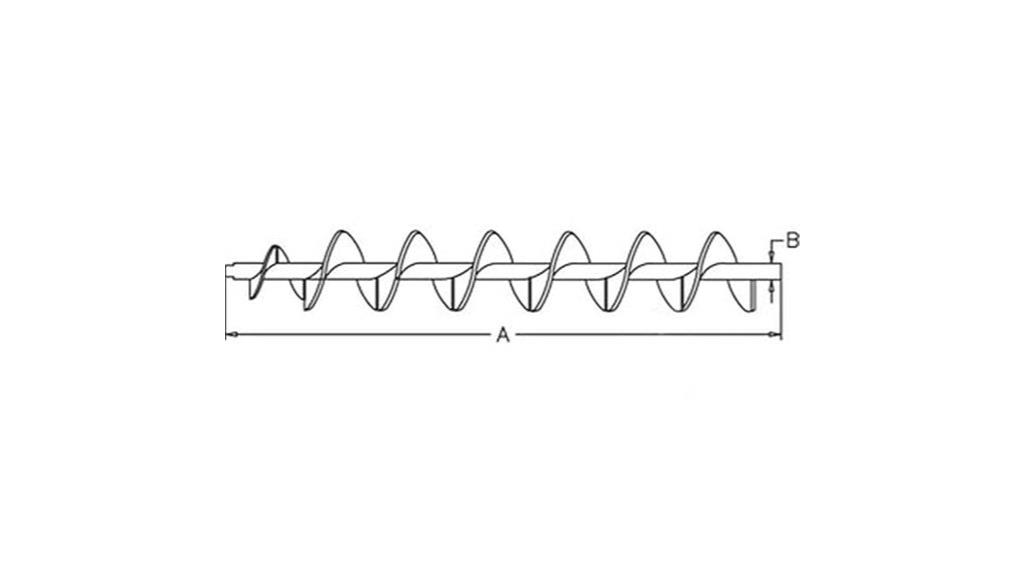

RAParts Grain Bin Loading Auger for Gleaner Combine 660 670 A65 A75 R52 R55

If you’re looking for a reliable grain auger that can handle Gleaner combines like the 660, 670, A65, A75, R52, and R55, the RAParts Grain Bin Loading Auger is an excellent choice. This new aftermarket auger features extended wear flighting made of abrasion-resistant steel, guaranteeing durability during heavy use. With a length of 67.75 inches, it’s designed to fit specific models, replacing OEM parts like 71388940 and Lagbr42C. Built to meet or exceed OEM standards, it offers dependable performance for efficient harvesting. Always verify compatibility before ordering to ensure a perfect fit for your combine.

Best For: farmers and equipment operators seeking durable, reliable grain loading augers for Gleaner, Massey Ferguson, and Challenger combines.

Pros:

- Made with abrasion-resistant steel for extended wear and durability

- Designed to meet or exceed OEM specifications for reliable performance

- Compatible with multiple models including Gleaner 660, 670, A65, A75, R52, R55, and select Massey Ferguson and Challenger models

Cons:

- Does not include bin extension; additional parts may be required for full setup

- Compatibility verification needed prior to purchase to ensure proper fit

- Some images or listings may not precisely represent the actual product

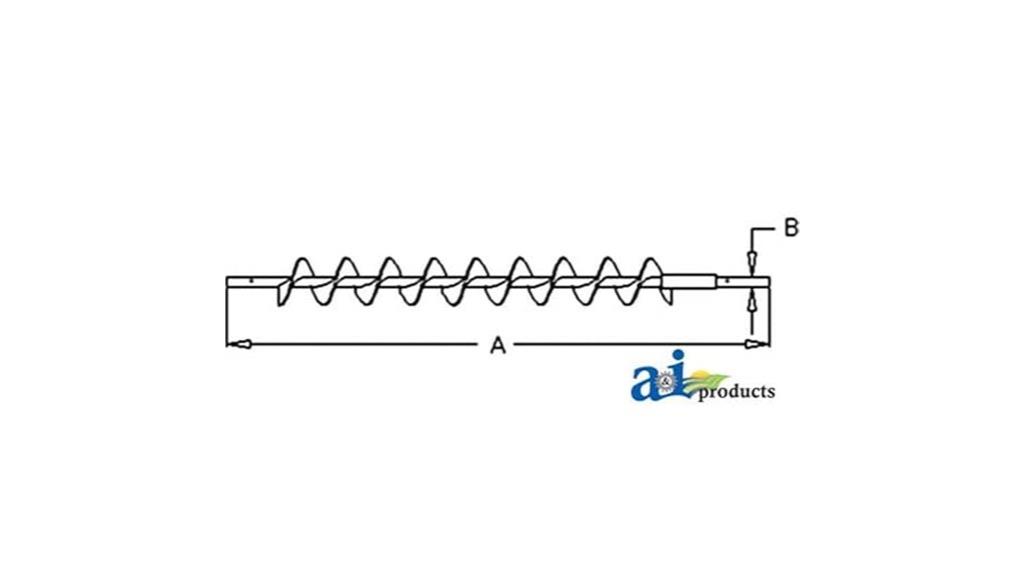

RAParts 71147888 Auger Grain Conveyor

Looking for a reliable grain conveyor that meets rigorous OEM standards? The RAParts 71147888 Auger Grain Conveyor is designed to match or exceed manufacturer specifications, ensuring dependable performance. While it’s an aftermarket part, it’s made to fit and function like the original. Be sure to verify OEM numbers for compatibility before ordering. This model offers a robust solution for efficient grain transfer, with quality built into its design. Keep in mind, some listings use stock images, so check the actual product to confirm features. If you need a solid, standards-compliant conveyor, the RAParts 71147888 is worth considering.

Best For: farmers and agricultural equipment operators seeking a durable, OEM-standard grain conveyor that ensures reliable and efficient grain transfer.

Pros:

- Meets or exceeds OEM specifications for quality and performance

- Compatible with a range of equipment when OEM numbers are verified

- Made as an aftermarket part with high standards for durability and functionality

Cons:

- OEM numbers should be verified for compatibility before purchase

- Actual product may differ from stock images shown in listings

- Being aftermarket, it may not have the exact original OEM branding or finish

RAParts AMAH136635 Grain Bin Loading Auger

The RAParts AMAH136635 Grain Bin Loading Auger stands out as an excellent choice for those seeking reliable aftermarket parts that meet or exceed OEM standards. Designed to replace the AH136635, it offers quality and performance assurance. While OEM numbers and logos are used for identification, it’s vital to verify compatibility before purchasing. This aftermarket auger is built to guarantee durability and efficient operation during harvest. Keep in mind, the actual product may differ from stock images, so checking detailed specifications is essential. Overall, this auger provides a dependable solution for grain bin loading needs in 2025.

Best For: farmers and agricultural professionals seeking a durable, reliable aftermarket grain bin loading auger that meets or exceeds OEM standards for efficient harvest operations.

Pros:

- Crafted to meet or surpass OEM specifications, ensuring high-quality performance

- Designed for durability and reliable operation during busy harvest periods

- Compatible with original equipment for easy replacement and installation

Cons:

- Actual product appearance may differ from stock images, requiring careful specification checks

- Compatibility must be verified prior to purchase to ensure proper fit

- Being an aftermarket part, it may not carry the same warranty coverage as OEM components

Electric Screw Conveyor Machine for Grains and Sand, 1500W Portable Powder Transfer Equipment

This electric screw conveyor machine stands out for its impressive capacity and versatility, making it an excellent choice for large farms, factories, and industrial operations. It can process 220-440 kg per minute, handling 12-24 tons per hour, which is three times faster than manual loading. Equipped with an 8-in-1 heavy-duty auger, it transports grains, sand, fertilizers, cement, and more, with flexible hose bends from 0° to 120°. Built with durable, wear-resistant materials, it offers easy operation with a one-touch switch, auto-overheat protection, and low maintenance. This equipment notably boosts efficiency, reduces labor costs, and ensures safe, reliable transfer of bulk materials.

Best For: large farms, factories, and industrial operations requiring fast, efficient bulk material handling and transfer.

Pros:

- High processing capacity of 220-440 kg/min, significantly boosting productivity

- Versatile with the ability to handle grains, sand, fertilizers, cement, and more

- Durable construction with wear-resistant steel pipes and flexible hoses for harsh environments

Cons:

- May require technical knowledge for setup and maintenance

- Potentially heavy and large, needing adequate space for installation

- Initial investment cost could be high for small-scale users

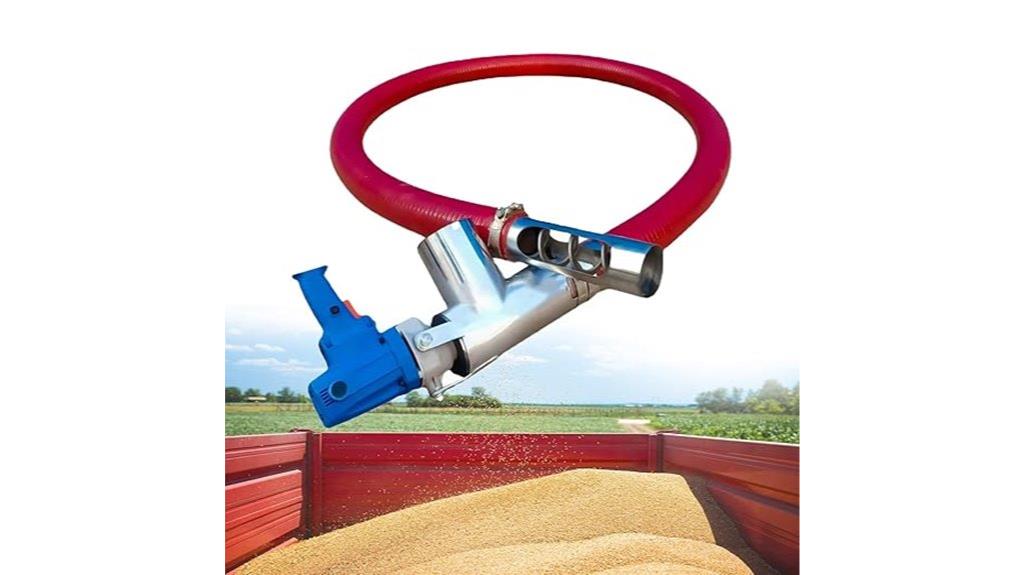

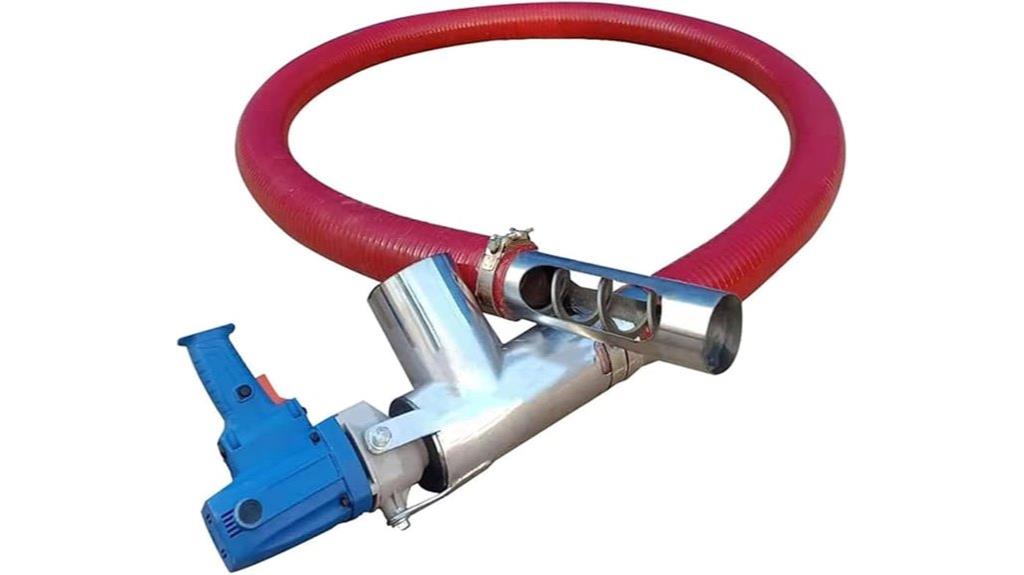

Grain Suction Pump with 6m Hose for Grain Transportation

For farmers seeking a reliable and portable solution to transport grain efficiently, the Grain Suction Pump with a 6m hose stands out as an excellent choice. Its lightweight design, weighing only 22 pounds, and compact dimensions make it easy to move around different workspaces. The pump’s durable stainless steel feed port resists wear, while the high-flexibility hose adapts seamlessly to narrow barns or uneven fields. With a powerful motor up to 2500W and simple one-button operation, it ensures quick, smooth grain transfer. Suitable for particles and similar materials, it’s perfect for those needing efficiency and portability in grain transportation.

Best For: farmers and agricultural workers seeking a portable, efficient, and durable grain transportation solution for use in narrow or uneven work environments.

Pros:

- Lightweight and portable at only 22 pounds with compact dimensions for easy maneuverability.

- Durable stainless steel feed port and high-flexibility hose ensure long-lasting performance and adaptability to various spaces.

- Powerful motor up to 2500W with simple one-button operation for quick and efficient grain transfer.

Cons:

- Not suitable for transporting water or wet materials, which can damage the equipment.

- Extended use may cause motor overheating, requiring external cooling or rest periods.

- Limited to specific particle types; may not handle excessively large or extremely wet materials effectively.

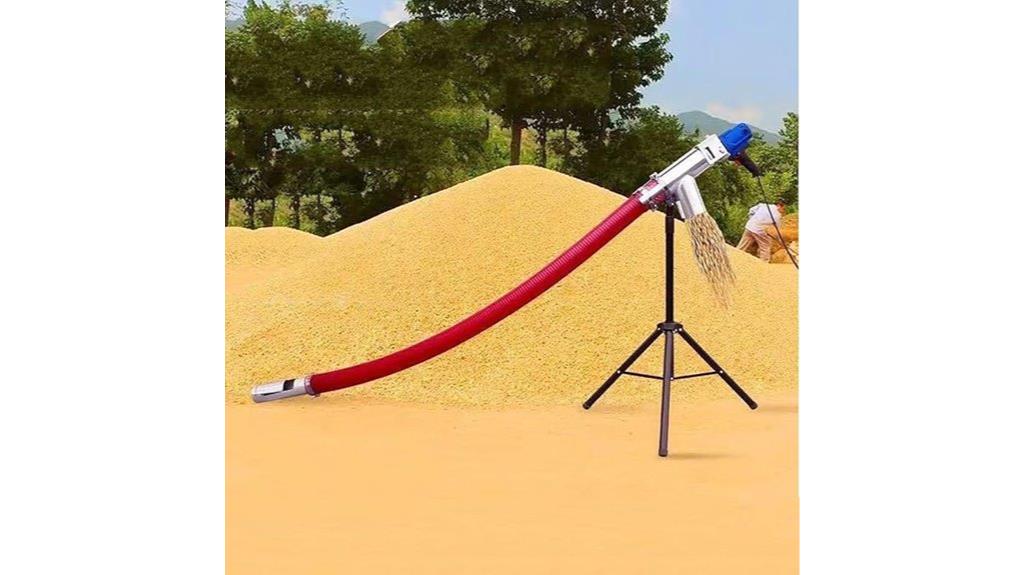

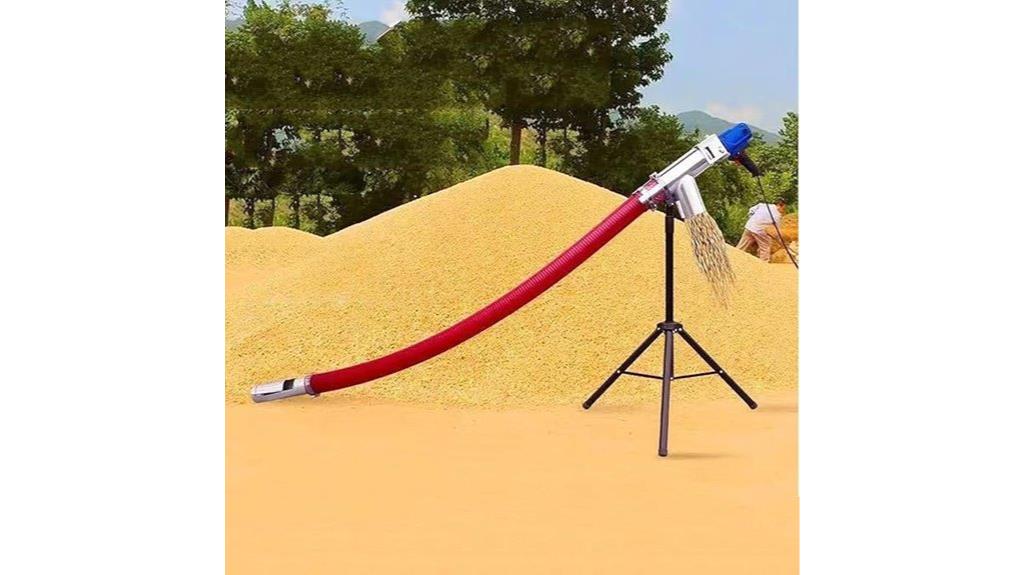

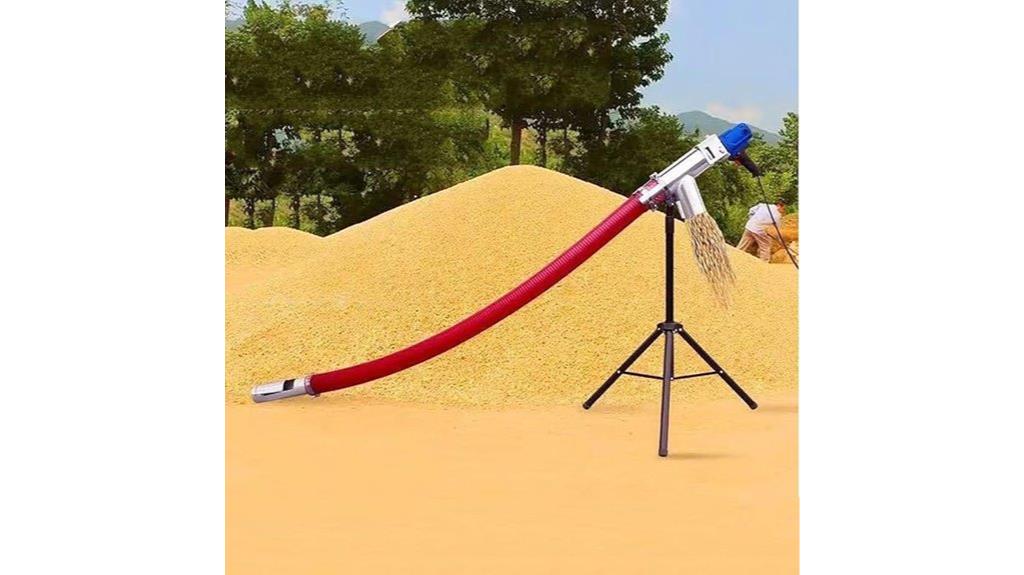

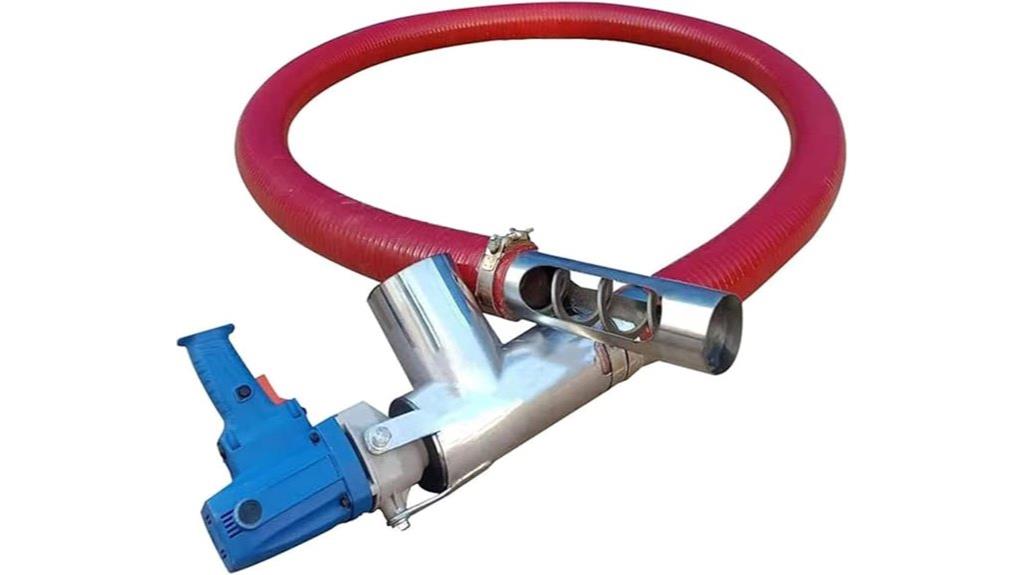

Grain Pumping Portable Grain Suction Auger Screw Conveyor

If you’re seeking a versatile solution for efficiently transferring grains, fertilizers, or cement across various applications, the Portable Grain Pumping Suction Auger Screw Conveyor stands out. It offers lengths of 2, 3, or 5 meters, powered by a 1500-2500W motor, with an output capacity of 220-440 lb/min. Its flexible hoses, available in multiple sizes, make setup easy across different environments. Built with a wear-resistant stainless steel feed port and reinforced rubber hoses, it ensures durability and smooth operation. Safety features like overheat protection and simple one-button controls make it user-friendly. Overall, it’s an adaptable, reliable tool for quick, efficient material transfer.

Best For: farmers, construction workers, and industrial providers needing efficient, portable material transfer for grains, fertilizers, cement, or gravel across varied environments.

Pros:

- Durable construction with wear-resistant stainless steel and reinforced hoses for long-term use

- Flexible hose options and multiple length choices adapt to different operational needs

- User-friendly features like one-button control and overheat protection ensure safety and ease of operation

Cons:

- Not suitable for transferring water-containing materials

- Limited warranty period of only 3 months may require additional coverage for long-term use

- High power consumption (1500-2500W) could increase operational costs during prolonged use

Grain Suction Machine, Portable Grain Pumping Conveyor (2m)

A portable grain suction machine with a 2-meter hose proves ideal for farmers and industrial operators seeking quick, efficient grain transfer. It’s designed to handle grains, seeds, pellets, and other dry materials, making loading and unloading trucks, silos, or storage bins straightforward. With a high-capacity screw conveyor and innovative suction cup, it can move 220–440 pounds per minute. The powerful 1500W–2500W motor ensures fast operation, while its lightweight, compact design makes it easy to transport and set up. Simple one-touch controls and minimal maintenance requirements enhance usability, making this machine a reliable choice for high-volume grain handling in demanding environments.

Best For: farmers, agricultural workers, and industrial operators seeking quick, efficient, and portable grain transfer solutions for loading and unloading grains, seeds, and dry granular materials.

Pros:

- High-capacity transfer rate of 220–440 lbs per minute, ensuring efficient workflow

- Lightweight and portable design for easy transport and setup in various environments

- Simple one-touch operation with minimal maintenance required, saving time and effort

Cons:

- Limited to dry, granular materials; not suitable for wet or damp substances

- Hose length options (2M, 3M, 5M) may require additional extensions for certain setups

- Power range may necessitate access to suitable electrical outlets, which could be a challenge in remote locations

Grain Pumping Machine Portable Suction Auger Screw Conveyor

The Grain Pumping Machine Portable Suction Auger Screw Conveyor stands out with its innovative one-button control system, making long-term operation straightforward and efficient. Its double reinforcement hoop allows easy caliber adjustments, ensuring a tight fit that prevents hose detachment while simplifying assembly and disassembly. The durable stainless steel feed port offers excellent hardness and wear resistance, supporting stable, high-pressure operation. Additionally, the strengthened rubber wire with a thickened rubber layer enhances wear resistance and extends the machine’s lifespan. With an ultra-flexible hose that adapts to various environments, this conveyor is versatile, reliable, and user-friendly, ideal for handling different particles like grain, cement, and fertilizer over a 6-meter length.

Best For: farmers, construction workers, and industrial operators seeking a reliable, easy-to-use portable conveyor for transferring grain, cement, fertilizer, and other particles efficiently.

Pros:

- Simplifies operation with an intuitive one-button control system.

- Durable construction with stainless steel and reinforced rubber components for long-lasting performance.

- Highly flexible hose allows for easy maneuverability in various environments.

Cons:

- Limited to a 6-meter length, which may not suit very large-scale operations.

- Requires careful handling during assembly due to calibration adjustments.

- May be less effective for very coarse or heavy materials beyond its specified particle types.

2 x 24 Inch Auger Drill Bits for Planting Bulbs

Designed for gardeners and landscapers seeking reliable planting tools, the 24-inch auger drill bits with a 2-inch diameter offer an excellent solution for efficient bulb planting. Made of heavy-duty alloy steel, these bits feature integral welding technology that enhances durability and guarantees long-term use. Their surface is painted to prevent corrosion and rust, maintaining performance over time. Compatible with 3/8 inch hex drive drills, they allow for simple, efficient operation, reducing bending and labor effort. Perfect for pot, garden, or orchard planting, these auger bits streamline soil preparation, making planting faster and less strenuous. Sometimes sold as a pair, they’re a reliable addition to any planting toolkit.

Best For: gardeners, landscapers, and DIY enthusiasts seeking durable, efficient auger bits for planting bulbs, soil preparation, and soil mixing tasks.

Pros:

- Made of heavy-duty alloy steel for enhanced durability and long-term use

- Compatible with 3/8 inch hex drive drills for easy operation

- Surface painted to prevent corrosion and rust, ensuring reliable performance over time

Cons:

- May require specific drill compatibility, limiting use with other drill types

- Length of 24 inches might be cumbersome in tight or confined spaces

- Sold as a pair or single piece, which may not suit all project needs

Grain Suction Machine, 5m Hose, Blue

For those seeking reliable grain transfer solutions, the Grain Suction Machine with a 5m blue hose stands out thanks to its large suction capacity and flexible design. Its stainless steel feed port guarantees durability, wear resistance, and corrosion resistance, making it suitable for heavy-duty use. The thickened rubber wire enhances wear resistance during operation, while the double reinforced hoop allows easy disassembly and prevents hose detachment. The flexible, blue hose length of 5 meters provides excellent operational reach for various tasks. With a one-key run switch, it supports long-duration work, making it ideal for household, agricultural, or industrial grain pumping. Overall, it’s a durable, versatile choice.

Best For: Farmers, homeowners, and industrial workers needing reliable, versatile grain transfer and pumping solutions.

Pros:

- Durable stainless steel feed port resists wear, pressure, and corrosion.

- Flexible, 5-meter blue hose offers excellent reach for various tasks.

- One-key run switch enables continuous operation for long durations.

Cons:

- May be heavier due to high-quality, reinforced materials.

- Limited to grain transfer, not suitable for other materials.

- Requires proper handling to prevent hose detachment despite reinforced hoops.

TECHTONGDA Stainless Steel Screw Conveyor with Hopper

If you’re seeking a reliable and efficient solution for material transfer, the TECHTONGDA Stainless Steel Screw Conveyor with Hopper stands out thanks to its powerful 1100W motor and durable stainless steel construction. It offers a 1.65-meter effective conveying height and a capacity of 600 pounds per minute, making it suitable for quick, large-volume handling. Its rigid drive shaft and spiral blades ensure smooth operation and easy maintenance, while the lightweight, corrosion-resistant design simplifies handling and cleaning. Ideal for conveying powders and small particles in industries like grain processing and construction, it combines safety, low noise, and dust-free operation for indoor use.

Best For: industries requiring efficient, large-volume conveying of powders and small particles such as grain processing, construction, and manufacturing.

Pros:

- Powerful 1100W motor ensures high efficiency and quick material transfer

- Durable stainless steel construction provides corrosion resistance and longevity

- Low-noise, dust-free operation ideal for indoor environments

Cons:

- Limited to conveying small particles and powders, not suitable for large or bulky materials

- Requires some assembly and maintenance knowledge for optimal operation

- May be less effective for conveying materials with high moisture content or sticky properties

RAParts AMAH127730 Grain Bin Loading Auger

The RAParts AMAH127730 Grain Bin Loading Auger stands out as an excellent choice for those seeking a reliable aftermarket replacement for John Deere Combine 8820 models. This auger measures 76.5 inches in length and features extended wear capabilities, ensuring durability during demanding harvests. Its double flight design helps improve efficiency by moving grain smoothly and quickly. While it’s designed to meet or exceed OEM standards, it’s essential to verify fit before ordering. With compatible OEM numbers like AH98032 and AH113813, this auger offers a cost-effective solution without sacrificing performance. It’s an excellent option for keeping your combine running at peak efficiency.

Best For: farmers and equipment operators seeking a durable, OEM-compatible replacement grain bin loading auger for John Deere 8820 combines.

Pros:

- Made to meet or exceed OEM standards for reliable performance

- Features extended wear for increased durability during demanding harvests

- Double flight design enhances grain movement efficiency

Cons:

- Verify fit before ordering to ensure compatibility

- May differ slightly in appearance from stock images

- OEM numbers are for reference only and do not guarantee fit without verification

RAParts Grain Auger Trough Tube for Case-IH Combine Models 2144

When selecting a grain auger trough tube, compatibility with specific combine models is vital, and the RAParts Grain Auger Trough Tube stands out for Case-IH Model 2144. This aftermarket part is designed specifically for this model, guaranteeing a proper fit and reliable performance. Manufactured to meet or exceed OEM standards, it offers high-quality durability for demanding harvesting conditions. While some listings may use stock images, it’s essential to verify compatibility before ordering. This trough tube is a dependable choice for those looking to maintain or restore their Case-IH 2144’s efficiency and ensure smooth grain flow during harvest.

Best For: farmers and equipment technicians seeking a reliable, high-quality replacement grain auger trough tube for Case-IH Model 2144 combines.

Pros:

- Designed specifically for Case-IH Model 2144, ensuring a perfect fit

- Manufactured to meet or exceed OEM standards for durability and performance

- Easy to install, helping maintain or restore harvesting efficiency

Cons:

- May require verification of compatibility before purchase due to stock image usage in listings

- As an aftermarket part, it might not include all original OEM features or markings

- Availability may be limited depending on supplier stock levels

Factors to Consider When Choosing a Grain Auger

When choosing a grain auger, I focus on how well it fits my equipment and the right size for my operation. I also consider the materials and build quality to guarantee durability, along with power efficiency for smooth performance. Ultimately, I look for models that are easy to install and handle to save time during busy harvest seasons.

Compatibility With Equipment

Ensuring compatibility between your grain auger and existing equipment is essential for smooth operation and avoiding costly mistakes. I always verify that the OEM part number of the auger matches my equipment’s specifications to guarantee a proper fit. It’s also critical to check compatibility with specific combine or tractor models, like John Deere 8820 or Case-IH 2144, before buying. I pay attention to the auger’s length and diameter to match my grain bin size and unloading height correctly. Additionally, I confirm that the flighting design and material meet or exceed OEM standards for durability and efficiency. Reviewing manufacturer compatibility charts and OEM replacement numbers helps me prevent mismatches and ensures seamless integration with my equipment, making harvest smooth and hassle-free.

Auger Length and Size

Choosing the right auger length and size is essential for efficient grain transfer. The auger length should match the height of your grain bin and the distance to the unloading or filling point, ensuring smooth flow without unnecessary stops. Common diameters range from 4 to 12 inches; larger diameters handle higher flow rates and bulk quantities better. Picking an auger size that suits your grain type and flow needs helps prevent blockages and minimizes wear. Keep in mind, longer augers may need reinforced construction or support to avoid bending or sagging during operation. Additionally, the overall size must fit with your existing machinery and available space, promoting safe and effective use. Proper sizing is vital for maximizing efficiency and durability in your harvesting setup.

Material and Durability

The material quality of a grain auger directly impacts its lifespan and ability to handle demanding agricultural tasks. I look for abrasion-resistant steels like AR400, which withstand constant wear from rough grains and debris. Durability is further boosted by thickened flighting and reinforced components that resist bending, cracking, and corrosion over time. High-quality stainless steel feed ports and rubber hoses also contribute to longevity, resisting pressure, wear, and environmental damage. Heavy-duty alloy steel combined with integral welding technology guarantees structural integrity during high-volume operations. Choosing materials with high hardness and pressure resistance helps maintain performance and reduces maintenance costs, especially in tough conditions. Ultimately, selecting durable, high-quality materials ensures your grain auger stays reliable season after season.

Power and Efficiency

Selecting a grain auger with the right power and efficiency features can substantially boost your harvest operation. Higher horsepower motors deliver more power, enabling faster transfer rates and improving overall efficiency. The auger’s flighting design, with extended wear or abrasion-resistant steel, ensures durability and continuous operation, reducing downtime. Choosing the ideal auger diameter and length is vital to maintain efficient throughput without causing blockages or wasting energy. Efficient gearboxes and drive systems minimize energy loss, maximizing power transfer while using less fuel or electricity. Additionally, proper alignment and balance of components reduce mechanical strain, leading to smoother operation and sustained efficiency over time. Focusing on these factors helps you select an auger that performs reliably and efficiently during the busy harvest season.

Ease of Installation

When evaluating grain augers, ease of installation plays a essential role in ensuring a smooth setup process. I look for models with user-friendly designs, such as quick-connect fittings and minimal assembly steps, which save time and effort. Compatibility with existing equipment and straightforward mounting points are fundamental, making installation simpler and faster. Lightweight construction and modular components help handle the auger easily and often eliminate the need for extra tools or personnel. Clear, detailed instructions and pre-assembled parts ensure proper setup without requiring extensive technical skills. Features like adjustable brackets and flexible sections allow for quick alignment and secure attachment, streamlining the entire process. Overall, a grain auger that’s easy to install helps me get to work faster and reduces setup frustrations.

Maintenance and Durability

Maintenance and durability are key factors I consider to keep my grain auger running smoothly over time. I look for models built from abrasion-resistant steel like AR400, which withstands harsh conditions. Regular inspections of flighting components and bearings are essential to prevent wear and keep efficiency high. I prefer augers with reinforced joints and corrosion-resistant coatings, as these resist moisture and corrosive materials. Sturdy, high-quality drive shafts and reinforced troughs reduce mechanical failure risks, ensuring long-term reliability. Additionally, I check the manufacturer’s warranty and support options, making repairs easier and more cost-effective. Investing in durable materials and thoughtful design helps me minimize downtime and extend the lifespan of my equipment, making harvest season much more manageable.

Frequently Asked Questions

What Is the Maximum Grain Capacity of These Augers?

The maximum grain capacity of these augers varies depending on the model, but most can handle between 1,000 and 2,500 bushels per hour. Some larger, commercial-grade augers reach capacities of up to 3,000 bushels per hour. I recommend checking the specific specifications of each model to guarantee it meets your harvesting needs, especially if you’re dealing with large-scale operations.

Are These Augers Compatible With All Combine Models?

Most grain augers are designed to be compatible with a wide range of combine models, but I always recommend checking the specific model and manufacturer’s guidelines. Compatibility can vary based on the auger’s size and mounting system. I suggest consulting the product specifications or speaking directly with the supplier to ensure the auger you choose will work seamlessly with your combine for efficient harvesting.

How Easy Is It to Assemble and Disassemble These Grain Augers?

I find that assembling and disassembling these grain augers is quite straightforward, especially with the clear instructions and user-friendly designs. I usually set aside some time, follow the step-by-step guide, and it’s done quickly. The modular components make it easy to break down for transport or storage. Overall, I’d say most users find the process manageable, even if they’re new to equipment setup.

What Safety Features Are Included in These Augers?

Think of these augers as your vigilant farm guards. They come equipped with safety features like emergency shut-off switches, guarding around moving parts, and safety decals to alert you of hazards. Some models even have slip clutch systems to prevent overloads. These features work together to keep you safe during operation, giving you peace of mind while you focus on the harvest.

How Do These Augers Perform With Different Types of Grains?

I’ve found that these augers perform reliably across various grains like wheat, corn, and soybeans. They handle different textures and weights smoothly, thanks to adjustable speeds and powerful motors. I notice minimal grain clogging or spillage, which boosts efficiency. Overall, they’re versatile tools that adapt well to diverse harvesting needs, making my work easier and faster regardless of what crop I’m processing.

Conclusion

So, when you finally decide on the perfect grain auger, remember it’s not just about effortless harvesting—it’s about avoiding a grain avalanche that turns your shed into a cereal tsunami. With all these top picks, you’d think choosing one’s a breeze, right? Just don’t forget, the real challenge is resisting the urge to test them all at once and turning your farm into a grain museum. Happy harvesting!