If you’re looking to boost your loader’s efficiency, I recommend exploring versatile attachments like bale spears, clamp-on pallet forks, debris forks, and quick-connect adapters. Heavy-duty materials, easy installation, and compatibility with your equipment are key features to contemplate. These attachments can handle tasks from moving hay bales to clearing debris efficiently. To find the top options suited for your needs, stick around; I’ll share more details to help you choose the right tools.

Key Takeaways

- Choose versatile attachments like bale spears, pallet forks, and debris forks to handle multiple tasks efficiently.

- Prioritize heavy-duty, durable materials such as alloy steel and reinforced welds for long-lasting performance.

- Opt for quick-attach and clamp-on designs to reduce installation time and maximize operational uptime.

- Ensure compatibility with your loader’s bucket size and mounting system for safe, efficient operation.

- Select attachments with adjustable features (e.g., stabilizer bars, forks) to adapt to various load types and improve productivity.

Front Loader Hay Bale Spear Attachment with 2 x 39 Bale Spears, Rated 3000 LB

If you’re looking for a reliable attachment to handle large hay bales, the Front Loader Hay Bale Spear with 2 x 39-inch spears is an excellent choice, especially since it’s rated to lift up to 3000 pounds. It features two high-tensile, replaceable square taper spears that are 39 inches long (34 inches usable). Designed for universal fitment, it works with buckets up to 3/4 inch lip thickness and at least 32 inches inside width. The pre-assembled frame with chains and binders allows quick setup, providing secure grip and stability for efficient lifting and transport of heavy hay bales.

Best For: farmers, landscapers, or agricultural workers needing a durable, easy-to-attach bale spear for handling large hay bales up to 3000 lbs.

Pros:

- Quick and tool-free assembly with pre-assembled frame, chains, and binders

- Universal fitment accommodates buckets with lip thickness up to 3/4 inch and 32 inches or more inside width

- High-tensile, replaceable spears ensure durability and reliable performance

Cons:

- May not fit buckets with lips thicker than 3/4 inch or inside width less than 32 inches

- Only rated for bales up to 3000 lbs, limiting use for heavier loads

- Does not include additional mounting hardware or tools, which may be needed for certain bucket types

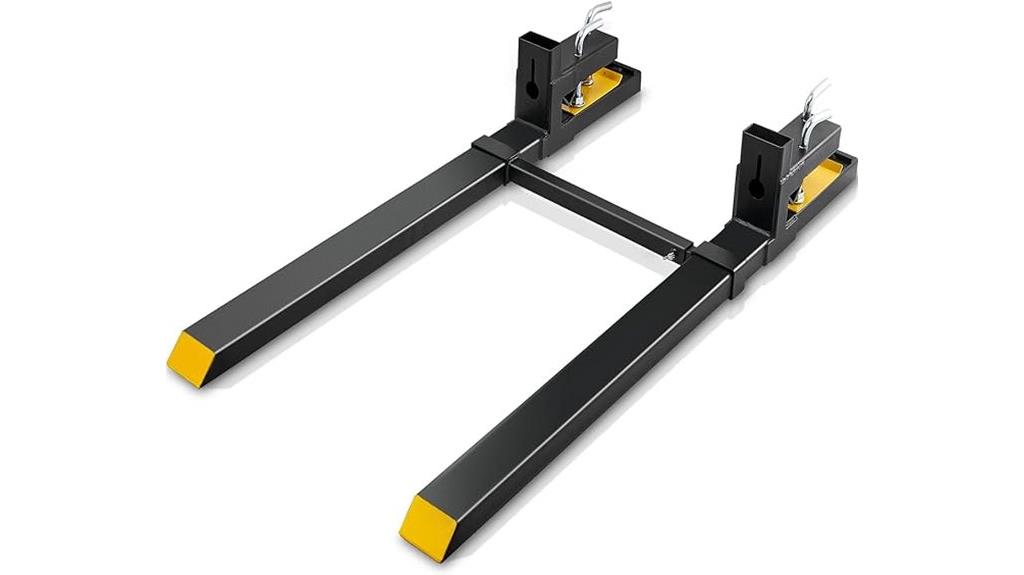

VEVOR Pallet Forks, 2000 lbs Clamp on Pallet Forks

The VEVOR Pallet Forks are an excellent choice for those who need a reliable, heavy-duty attachment capable of handling up to 2000 pounds. Made from durable square steel tubing, they won’t bend or crack under load, and reinforced bolts ensure stability. The clamp-on design makes installation quick and straightforward—simply slide over bucket edges and clamp down. An adjustable stabilizer bar (19.5 to 36 inches) prevents separation during heavy lifting, enhancing safety. With a 60-inch overall length and 43-inch forks, they’re versatile for moving logs, hay, debris, and more, making them ideal for farms, construction, and warehouses.

Best For: individuals and professionals in farming, construction, or material handling who need a heavy-duty, reliable clamp-on pallet fork attachment capable of lifting up to 2000 lbs.

Pros:

- Durable construction from square steel tubing ensures strength and longevity

- Easy clamp-on installation compatible with most tractor buckets

- Adjustable stabilizer bar enhances safety by preventing separation under load

Cons:

- Fixed fork dimensions may not suit all equipment sizes or specific lifting needs

- Heavier weight of the attachment could impact maneuverability

- Requires proper maintenance of bolts and stabilizer bar to ensure continued safety

VEVOR Pallet Forks, 4000 lbs Clamp on Pallet Forks

VEVOR Pallet Forks are an excellent choice for anyone needing a durable, budget-friendly attachment capable of handling heavy loads up to 4000 lbs. Made from tough square steel tubing, they’re built for heavy-duty tasks without bending or cracking. The set includes two forks, a stabilizer bar, and easy-to-follow instructions. With a 60-inch overall length and adjustable stabilizer, these forks fit most tractors, including John Deere and Kubota, and clamp securely onto buckets. Users praise their stability, affordability, and versatility for moving pallets, logs, or debris. While some tightening may be needed, they represent a solid, cost-effective solution for many lifting needs.

Best For: budget-conscious farmers, contractors, and DIY enthusiasts seeking a heavy-duty, easy-to-install pallet fork attachment for light to moderate lifting tasks.

Pros:

- Constructed from durable square steel tubing rated for 4000 lbs capacity, offering strong load support

- Easy to install and remove, fitting most tractors and buckets quickly

- Affordable alternative to high-end brands with good overall stability and versatility

Cons:

- Clamp screws may require additional tightening with tools like a pipe wrench for secure attachment

- Basic welds and potential packaging issues may affect durability or lead to missing parts

- Sideways deflection under heavy or angled loads, and limited customer service for parts replacement

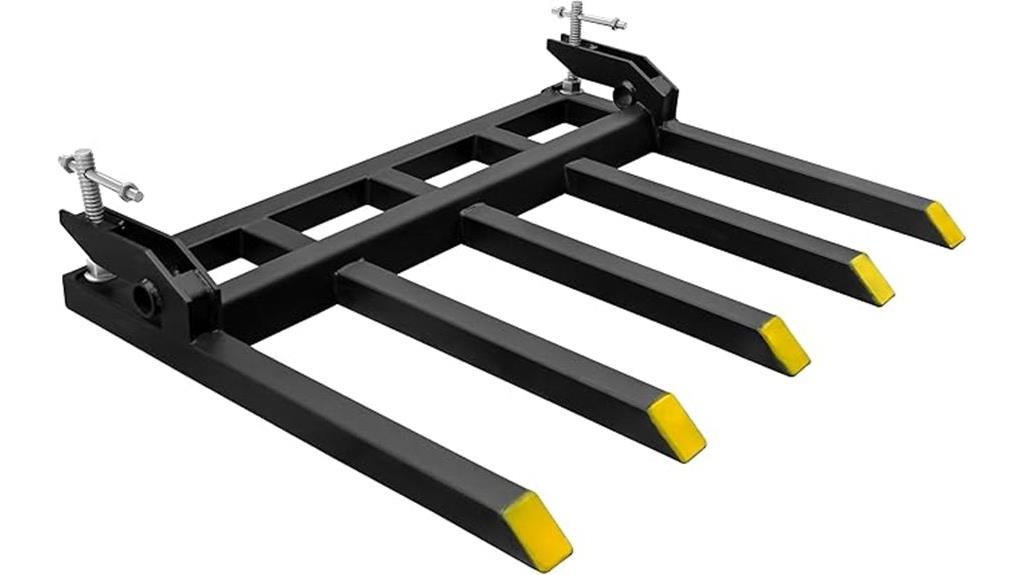

Clamp On Debris Forks for Buckets and Skidsteer Attachments

Clamp On Debris Forks are an excellent choice for those seeking a quick, secure way to enhance their loader buckets and skid steer attachments. These versatile forks are designed to handle logs, hay bales, debris, and other materials efficiently. Made from high-strength steel with a durable powder coat, they resist corrosion and fading. Installation is easy—simply slide over the bucket edge and clamp down. Supporting up to 2,500 lbs, they’re perfect for farms, factories, or warehouses. With a compact 48-inch size and quick attachment, these debris forks boost productivity and make material handling safer and faster.

Best For: Farm, factory, and warehouse operators seeking a quick, secure solution for handling logs, hay bales, debris, and palletized loads with their loader buckets or skid steer attachments.

Pros:

- Easy to install with a simple slide-over and clamp design, saving time and effort

- Constructed from high-strength steel with a durable powder coat for corrosion and fade resistance

- Supports a maximum load of 2,500 lbs, making it suitable for heavy-duty material handling

Cons:

- Limited to 48-inch bucket widths; may not fit larger or custom-sized buckets

- No automated or powered features; operation relies on manual handling and clamping

- Customer reviews indicate varied satisfaction, with some noting fit or attachment issues

VEVOR Pallet Forks, 2000 Lb Clamp-On Forks for Tractors

If you’re looking for a reliable attachment to handle heavy lifting tasks with your tractor, these VEVOR Pallet Forks are an excellent choice. Designed to clamp onto tractor buckets, they measure 43 inches long with a 30-inch fork blade, supporting up to 2000 pounds. Made from durable square steel tubing, they’re built for strength and durability. The adjustable stabilizer bar ensures safety and stability during operation, preventing separation under heavy loads. Easy to install by sliding over bucket edges and clamping, these forks are versatile for moving logs, hay bales, or debris. Overall, they’re a practical, solid solution for material handling needs.

Best For: those in farming, gardening, or material handling who need a durable, easy-to-install clamp-on fork attachment for their tractor or skid steer.

Pros:

- Supports a maximum load capacity of 2000 pounds, suitable for heavy-duty tasks

- Made from durable square steel tubing for strength and resistance to bending

- Adjustable stabilizer bar enhances safety and prevents separation under heavy loads

Cons:

- Weighs approximately 41.4 pounds, which may require effort to handle during installation

- Clamping installation may not be compatible with all bucket types or sizes

- Limited to manual operation without powered assistance, potentially requiring additional effort for very heavy loads

ECOTRIC Universal 3-Point Attachment Adapter

The ECOTRIC Universal 3-Point Attachment Adapter is an excellent choice for farmers, implement dealers, and large equipment fleets seeking versatile compatibility. Its adjustable width lift arms, from 8 to 43 inches, fit a wide range of vehicles, including skid steer loaders, tractors, and backhoes. Made from durable steel alloy with a powder-coated finish, it’s built to withstand demanding tasks like snow removal and debris disposal. The easy-to-install skid steer style mount allows quick attachment changes, while its robust construction guarantees stability and safety during operation. This adapter maximizes equipment flexibility, making it a practical addition for various heavy-duty applications.

Best For: farmers, implement dealers, and large equipment fleets seeking versatile, durable attachment solutions for various heavy-duty tasks.

Pros:

- Adjustable width lift arms from 8 to 43 inches for broad compatibility

- Constructed from heavy-duty steel alloy with a powder-coated finish for durability

- Easy skid steer style mount enables quick attachment and detachment

Cons:

- Does not include an instruction manual, which may complicate setup for some users

- Heavyweight (approximately 124 pounds) may require additional effort to handle

- Compatibility limited to category 1 implements not driven by PTO shafts

VEVOR Clamp-on Debris Forks for 48-Inch Bucket

Designed for loaders, skid steers, and tractors handling debris cleanup, VEVOR Clamp-on Debris Forks are an excellent choice for those needing a sturdy, easy-to-install attachment. They fit 48-inch buckets and support up to 2,600 lbs, making them perfect for hauling branches, small logs, and yard waste. Constructed from durable Q345 alloy steel with seamless welding, they resist fractures and corrosion. The curved shank design reduces effort during use, and the clamp system ensures secure attachment. Lightweight and straightforward to install or remove, these forks greatly improve efficiency in landscaping and land clearing projects. Overall, they’re a reliable tool for debris management tasks.

Best For: property owners, landscapers, and contractors needing durable and efficient debris cleanup attachments for loaders, skid steers, and tractors.

Pros:

- Made from tough Q345 alloy steel with seamless welding for added strength and durability.

- Easy to install and remove with a bolt-clamping system, reducing setup time.

- Lightweight design improves maneuverability and reduces operator fatigue during use.

Cons:

- Bolts may loosen or fall out over time; locking nuts or thread-locking compounds are recommended.

- End caps can detach if subjected to excessive force or heavy loads.

- Tines may bend under very heavy or improper loads, requiring careful handling during heavy-duty tasks.

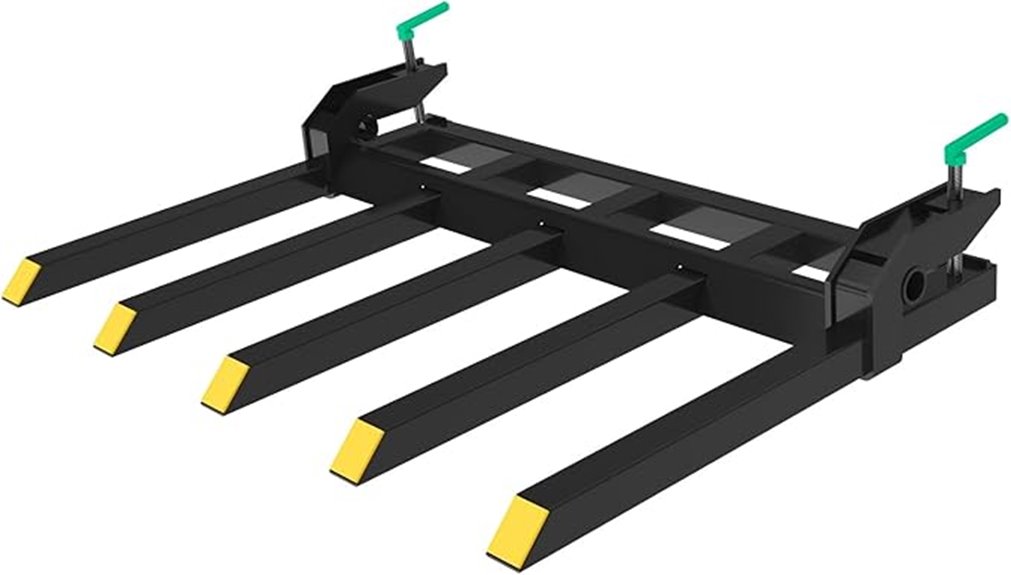

YITAMOTOR Clamp on Debris Forks for 48 Bucket

YITAMOTOR Clamp on Debris Forks are an excellent choice for those needing a sturdy, easy-to-install attachment for 48-inch or larger buckets. Made of high-quality materials with a rust-resistant coating, they support up to 2,500 lbs and feature five 21-inch tines. Installation is straightforward—simply slide the forks over the bucket edge and clamp securely. These forks are perfect for hauling logs, debris, firewood, or hay bales, making your work faster and more efficient. Compatible with most standard 48-inch or bigger buckets, they’re a versatile tool that boosts productivity on farms, warehouses, and construction sites.

Best For: Farmers, warehouse workers, and construction professionals needing a durable, easy-to-install debris handling attachment for large buckets.

Pros:

- Supports up to 2,500 lbs, making it suitable for heavy-duty lifting tasks

- Made of high-quality, rust-resistant materials for durability and longevity

- Easy to install by sliding over bucket edges and clamping securely

Cons:

- Designed specifically for 48-inch or larger buckets, limiting compatibility with smaller buckets

- Weighs approximately 75 pounds, which may require additional effort to handle during installation

- No batteries required, but manual installation may be time-consuming for some users

YINTATECH Heavy Duty Tractor Forks with Clamp-On Pallet Forks and Stabilizer Bar

If you need reliable forklift attachments that can handle heavy loads on farms or construction sites, YINTATECH Heavy Duty Tractor Forks with Clamp-On Pallet Forks and Stabilizer Bar are an excellent choice. These forks fit most loader bucket skid steer tractors and heavy-duty equipment, supporting loads up to 4,000 lbs. They’re easy to install — just slide over the bucket edge and clamp. Made from coated welded steel with sturdy rectangular tubes, they’re built for durability and safety. The adjustable stabilizer bar offers stability from 18 to 34 inches, making handling logs, hay bales, or debris safer and more efficient.

Best For: farmers, construction workers, and landscapers seeking durable, easy-to-attach pallet forks for heavy lifting tasks with their skid steer tractors or heavy-duty equipment.

Pros:

- Compatible with most loader bucket skid steer tractors and farm equipment for versatile use

- Constructed from coated welded steel with thick rectangular tubes for enhanced durability and safety

- Adjustable stabilizer bar from 18 to 34 inches improves stability and handling safety

Cons:

- May require manual adjustment for different machinery setups, which could take additional time

- Designed specifically for heavy loads up to 4,000 lbs, possibly limiting lighter-duty applications

- Installation, while straightforward, may need to be checked periodically to ensure clamps remain secure

YITAMOTOR 39 Hay Spear Bale Spears Universal HD Front Skid Steer Tractor Loader Bucket Attachment

This heavy-duty hay spear attachment is perfect for farmers and landscapers who need a reliable tool for handling large round hay bales efficiently. The YITAMOTOR 39 Hay Spear Bale Spears features a robust 3,000-pound capacity, making it suitable for demanding agricultural tasks. It includes one 39-inch hay spear and two stabilizer spears, all securely welded for strength. With a powder-coated finish, it resists rust and wear, ensuring long-term durability. Easy to install—simply hook onto your front loader and tighten the chain—it helps reduce manual labor and speeds up hay handling, feeding, and transportation. Weighing 93 pounds, it’s a versatile addition to any farm or landscape operation.

Best For: farmers, landscapers, and livestock owners needing a durable, efficient tool for handling large round hay bales with ease and safety.

Pros:

- Heavy-duty construction rated for 3,000 LB capacity ensures reliable performance.

- Quick and easy installation via floor mount system reduces setup time.

- Powder-coated finish provides excellent rust and corrosion resistance, extending product lifespan.

Cons:

- Weighs 93 pounds, which may require additional effort to handle during installation.

- Limited to use with front loaders and skid steers, not compatible with other machinery.

- Does not include additional accessories or mounting options beyond the standard setup.

Titan Attachments Dual Prong Hay Bale Spear Attachment

The Titan Attachments Dual Prong Hay Bale Spear Attachment is an excellent choice for farmers and ranchers who need a reliable, heavy-duty tool to handle large hay bales. It easily mounts to all brands of front loader or skid steer buckets, sliding over the cutting edge for quick setup. With two Conus 2 spears, chains, and ratchet binders, it supports loads up to 3,000 pounds. Made from durable steel tubing with a powder-coated finish, it’s built to withstand weather and heavy use. Its compact size and sturdy design make transporting, stacking, and feeding hay more efficient, saving time and effort on busy farm days.

Best For: farmers and ranchers who need a durable, heavy-duty bale handling attachment for efficient hay transportation and stacking.

Pros:

- Easy to install and remove, with a quick setup process taking approximately five minutes.

- Constructed from heavy-duty steel tubing with a powder-coated finish for durability and rust resistance.

- Supports loads up to 3,000 pounds, making it suitable for large round and square hay bales.

Cons:

- The attachment’s weight (around 106-108 pounds) can make handling and mounting challenging without assistance.

- Some users have experienced bent spears or chain clip breakage, requiring modifications or replacements.

- Requires consideration of tractor size and weight distribution, especially when handling very heavy bales that may need counterweights.

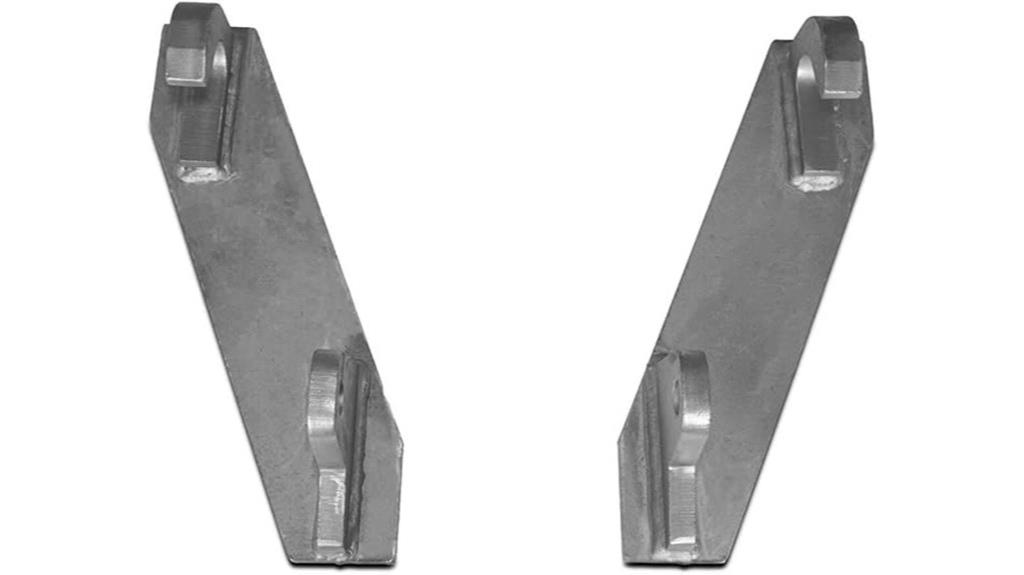

Titan Attachments Mounting Brackets Pair for John Deere Euro Loaders

Designed specifically for John Deere Euro loaders, Titan Attachments’ mounting brackets pair offers a heavy-duty solution for attaching bale spikes, brush rakes, and other equipment. Made from Grade 50 steel with 1/4-inch thick base plates, these brackets are built to withstand demanding workloads. Each weighs around 33-34 pounds, ensuring durability without excessive weight. They fit euro global loaders and are compatible with NH loader attachments, though they don’t suit standard JD Quick Tach. Customers praise their exact fit and rugged construction, although some note that installation requires careful measurement. Overall, these brackets boost attachment versatility and strength, making them a smart upgrade for demanding tasks.

Best For: contractors and farm owners needing heavy-duty, precise mounting brackets for John Deere Euro loaders to attach bale spikes, brush rakes, and similar equipment.

Pros:

- Heavy-duty construction with Grade 50 steel for durability

- Exact fit for John Deere Euro global loaders, ensuring reliable attachment

- Compatible with NH loader attachments and suitable for demanding applications

Cons:

- Installation may require careful measurement and adjustment

- Weld quality varies among users, potentially affecting strength

- Not compatible with standard JD Quick Tach loaders

Titan Attachments Hay Bale Spear Attachment with Stabilizer Spears

If you’re looking for a reliable way to handle large round hay bales efficiently, the Titan Attachments Hay Bale Spear Attachment with Stabilizer Spears is an excellent choice. It’s a heavy-duty, universal attachment with a 3,000-pound capacity, designed to tackle tough lifting and transportation tasks. Easy to install by attaching to your front bucket and tightening the chain, it also comes apart quickly when needed. Made from rust-resistant steel, it’s built to endure all weather conditions. The frame’s sturdy design, combined with stabilizer spears, ensures secure handling of bales, making it an essential tool for farms and livestock operations.

Best For: farmers, livestock handlers, and agricultural professionals needing a durable, reliable tool for handling large round hay bales efficiently.

Pros:

- Easy to install and remove, saving time during setup and cleanup

- Constructed from rust-resistant steel for durability in all weather conditions

- High capacity of 3,000 lbs ensures reliable performance with large bales

Cons:

- Weighs 82 pounds, which may be heavy to handle during installation

- Designed specifically for large round hay bales, limiting versatility for other tasks

- Requires proper attachment and tightening to ensure secure handling, which may need additional effort for first-time users

Titan Attachments 46 Fork Frame Attachment

The Titan Attachments 46 Fork Frame Attachment stands out as an ideal choice for farmers and loaders needing a versatile, heavy-duty option that fits a wide range of John Deere loaders. Its compatibility spans multiple series, including D120, D160, H120, 120R, 200X, 300X, and Ag loaders like 500 and 540. Built from powder-coated structural steel, it supports up to 4,500 pounds and features adjustable forks from 6 to 44 inches. The welded headache rack adds safety, while removable hay spears enable quick conversion for hauling hay, pallets, or logs. Lightweight at 120 pounds, it’s durable, adaptable, and designed for demanding agricultural tasks.

Best For: farmers and loaders seeking a heavy-duty, versatile frame attachment compatible with a wide range of John Deere loaders for transporting hay, pallets, logs, and debris.

Pros:

- Compatible with numerous John Deere loader models and Ag loaders, offering versatile use across equipment

- Constructed from durable, powder-coated structural steel supporting up to 4,500 pounds

- Removable hay spears for quick conversion between hauling hay, pallets, and logs

Cons:

- Tight fit of forks may require adjustments or modifications for optimal operation

- Some welding defects reported, such as lopsided hooks, affecting initial quality perception

- Occasional shipping damages noted, which may necessitate refunds or repairs

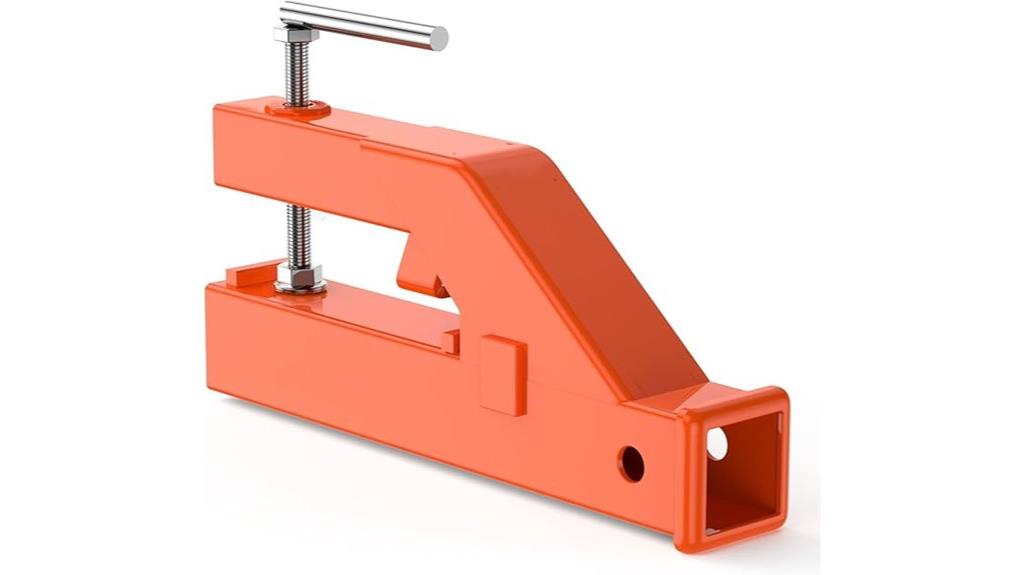

GARVEE Clamp-on Trailer Hitch Receiver for Front End Loader Bucket

The GARVEE Clamp-on Trailer Hitch Receiver is perfect for those who need a quick, reliable way to tow trailers using their front end loader or tractor bucket. It converts your tractor’s bucket into a standard 2×2-inch trailer hitch, making trailer movement simple and efficient. Installation is tool-free—just slide it onto your bucket and clamp down securely. No hassle or extra equipment required. This attachment is ideal for yard work, farm tasks, or construction projects involving frequent trailer repositioning. With the GARVEE hitch, you can quickly switch between tasks, saving time and effort while enhancing your loader’s versatility.

Best For: those who frequently need to tow trailers with their front end loader or tractor bucket, such as farmers, landscapers, and construction professionals.

Pros:

- Easy, tool-free installation and removal for quick setup

- Converts standard tractor buckets into versatile trailer hitches

- Ideal for efficient trailer movement in tight spaces and yard work

Cons:

- Designed specifically for 2×2 inch tractor buckets, limiting compatibility

- May not support very heavy or large trailers depending on tractor capacity

- Requires secure clamping to ensure safe towing during operation

Factors to Consider When Choosing Front‑End Loader Attachments

When selecting front-end loader attachments, I always start by considering if they’re compatible with my equipment and meet my load capacity needs. Ease of attachment and how quickly I can swap tools also matter, along with the durability of the materials used. Finally, I look for versatility to ensure the attachment can handle a variety of tasks efficiently.

Compatibility With Equipment

Choosing the right front-end loader attachment starts with guaranteeing it’s compatible with your equipment. First, check that the mounting system matches your loader’s type, whether it’s a universal skid steer, euro, or category 1 three-point hitch. Next, verify the attachment’s dimensions—width, height, and weight capacity—to make sure they align with your loader’s specifications and load requirements. It’s vital to confirm that the attachment’s design suits your loader’s brand and model, especially if it uses quick-attach or clamp-on systems. Additionally, review whether the connection points and hardware are compatible with your existing equipment’s standards. Guaranteeing compatibility prevents mishaps, reduces downtime, and guarantees that your attachment works seamlessly with your loader’s operating capacity and features.

Load Capacity Requirements

Ensuring your front-end loader attachment can handle the loads you plan to lift is essential for safe and efficient operation. I always start by determining the maximum weight of loads I need to lift regularly. This helps me select an attachment with a load capacity that exceeds this weight, providing a safety margin. I also make certain the attachment’s rated load capacity aligns with my loader’s lifting limits to prevent overloading, which could cause damage or failure. Considering future workload increases is wise; choosing a higher capacity attachment adds versatility and safety. Additionally, I verify that my loader’s hydraulic system and frame can support the attachment’s rated load capacity without strain. This careful consideration ensures ideal performance and safety during operation.

Attachment Ease & Speed

Quick and easy attachment changes can save a lot of time on the job site, keeping work flowing smoothly. Attachments with pre-assembled frames and tool-free mounting mechanisms make swapping tools faster and simpler. Designs that use chains, binders, or clamp-on features enable rapid installation without extra tools, reducing downtime. Compatibility with various bucket sizes and styles allows me to switch attachments efficiently based on the task at hand. Clear, straightforward mounting instructions and minimal loose parts further streamline the process, preventing delays. Choosing attachments that prioritize ease and speed guarantees I can transition quickly between jobs, maintaining productivity and reducing labor costs. When evaluating attachments, look for these features to maximize efficiency and keep your work on schedule.

Durability & Material Quality

When selecting front-end loader attachments, durability and material quality play a crucial role in their long-term performance. High-quality attachments are built from heavy-duty steel or alloy, which resist bending, cracking, and corrosion even under heavy use. The thickness of the material, like 1/4-inch or 3/8-inch steel, directly influences their ability to handle substantial loads without deforming. Weld quality is also vital; seamless, reinforced welds provide stronger bonds and prevent fractures during demanding tasks. Protective coatings such as rust-resistant finishes, powder coatings, or galvanization extend the lifespan by shielding against moisture and chemicals. Lastly, reinforced components like thick stabilizer bars and sturdy bolt holes ensure structural integrity, allowing the attachment to withstand repeated, extreme use over time.

Versatility in Tasks

Choosing the right front-end loader attachment depends heavily on its ability to perform multiple tasks efficiently. Versatile attachments can handle everything from lifting hay and moving logs to debris removal, making them essential for maximizing productivity. Many designs feature adjustable components like stabilizer bars or mounting brackets, allowing compatibility with different load sizes and equipment types. This flexibility means you can switch between attachments such as bale spears, pallet forks, and debris rakes quickly, saving time and effort. Durability is also key; a robust construction ensures the attachment withstands heavy workloads and harsh conditions without failure. By selecting versatile attachments, I can adapt to various tasks seamlessly, improving efficiency and guaranteeing my loader remains a multi-purpose tool for diverse jobs.

Safety Features & Stability

Selecting the right front-end loader attachment involves more than just versatility; safety features and stability are vital to guarantee secure operation and prevent accidents. Look for attachments with reinforced welds, stabilizer bars, or chain systems that prevent slippage during lifting. Safety features like locking pins, anti-slip surfaces, and overload capacity ratings help minimize risks. It’s essential to verify compatibility with your loader’s specs, including lip thickness and inside width, to maintain stability. Choose attachments made of heavy-duty steel frames with corrosion-resistant finishes to handle heavy loads safely. Additionally, opt for designs that allow easy installation and removal without compromising stability, enabling quick adjustments while keeping safety a top priority. Prioritizing these factors ensures safer, more reliable operation.

Cost & Budget Constraints

Budget constraints play a crucial role in determining which front-end loader attachments are feasible for your operation. The cost of these attachments varies widely, from around $100 for basic models to over $1,000 for specialized or heavy-duty options. Your decision should consider not just the initial purchase price but also ongoing costs like maintenance, replacement parts, and installation. Investing in higher-quality attachments might seem costly upfront but can save money long-term through better durability and safety. It’s imperative to evaluate how often and for what tasks you’ll use the attachments. If your workload is frequent and demanding, allocating funds toward durable, versatile options makes sense. Conversely, for occasional use, more economical, task-specific attachments might better fit your budget.

Maintenance & Replacement Parts

Regular inspection of front-end loader attachments is vital to guarantee safety and peak performance. I check components like chains, bolts, and welds regularly to spot wear, corrosion, or damage early. Using the right replacement parts, such as spears, stabilizer bars, and mounting brackets that match the original specifications, ensures proper fit and function. I always opt for manufacturer-approved parts to maintain the attachment’s integrity and preserve warranties. Keeping spare parts in stock for common replacements minimizes downtime and speeds up repairs. Additionally, proper maintenance—cleaning, lubrication, and timely replacements—extends the lifespan of critical parts and keeps the attachment operating reliably during heavy use. This proactive approach helps maximize efficiency and safety in my operations.

Frequently Asked Questions

How Do Attachment Compatibility Standards Vary Among Brands?

Attachment compatibility standards vary among brands because each manufacturer often designs their equipment with unique connection systems and specifications. I’ve learned to carefully check the compatibility before purchasing or switching attachments, as mismatched standards can cause safety issues or damage. It’s essential to consult the brand’s guidelines or use adapters when needed, ensuring your loader operates smoothly and efficiently with the right attachments.

What Safety Features Should I Look for in Attachments?

When choosing attachments, I look for safety features like locking mechanisms to prevent accidental detachment, quick-attach systems for secure and easy changes, and high-visibility labels for clear instructions. I also prioritize attachments with reinforced edges and safety guards to protect against damage or injury. It’s vital to guarantee the attachment meets safety standards and manufacturer guidelines, giving me peace of mind during operation and reducing the risk of accidents.

How Do Attachment Prices Compare Across Different Manufacturers?

Prices for front-end loader attachments can vary widely, so it pays to shop around. I’ve found that reputable manufacturers often charge a premium for better quality and durability, but sometimes you can find good deals from lesser-known brands. It’s a balancing act—investing in reliable attachments may cost more upfront but saves you money in repairs and downtime later. Don’t forget to take into account warranties and after-sales support when comparing prices.

What Maintenance Routines Extend Attachment Lifespan?

To extend your attachment’s lifespan, I recommend inspecting it regularly for wear, cracks, or damage. Lubricate moving parts frequently to prevent rust and assure smooth operation. Keep it clean, removing dirt and debris after use, and store it in a dry place when not in use. Additionally, follow the manufacturer’s maintenance schedule and replace worn parts promptly. Consistent care like this keeps your attachments working efficiently longer.

Are There Eco-Friendly Attachment Options Available?

Absolutely, eco-friendly attachment options are available! I’ve found that biodegradable materials and sustainably manufactured attachments help reduce environmental impact. Some companies now produce attachments made from recycled metals or eco-conscious composites. Using these not only minimizes your carbon footprint but also supports sustainable practices. I recommend exploring brands committed to green manufacturing, as they often offer innovative solutions that boost efficiency while caring for the environment.

Conclusion

Choosing the right front-end loader attachment is like finding the perfect tool in a toolbox—each one unlocks new efficiency and power. With the right attachment, you’ll turn your loader into a versatile workhorse, ready to tackle any task with ease. So, pick wisely, and watch your productivity soar like a bird on the wind—unstoppable and free, transforming your worksite into a well-oiled machine.