In mid-August, you should inspect and clean air filters and vents to prevent dust buildup, check hydraulic systems and fluid levels for peak performance, and lubricate moving parts to reduce wear. Examine belts, hoses, and connections for signs of wear or leaks, and test safety features and emergency stops to ensure they function properly. Maintain accurate records and schedule professional inspections to stay ahead. Keep going to discover more essential steps for keeping your equipment in top shape.

Key Takeaways

- Conduct air filter and vent inspections to prevent dust buildup and maintain airflow during mid-August.

- Schedule lubrication and belt checks to reduce friction and wear before seasonal peak demands.

- Perform safety feature tests, emergency stop checks, and hazard assessments for ongoing compliance.

- Review and update maintenance records with recent inspections and calibration data to ensure accuracy.

- Prepare machinery for seasonal changes by inspecting for environmental damage, corrosion, and performing preventive maintenance.

Inspect and Clean Air Filters and Vents

To guarantee your machinery runs efficiently, you should inspect and clean air filters and vents regularly. Poor air quality can lead to overheating and reduced performance, so keeping filters clean is essential. Check the filters for dirt, dust, or debris that can clog airflow. If filters appear dirty or damaged, replace them promptly to maintain ideal air quality. Regular filter replacement ensures your machinery operates smoothly and prevents dust buildup that can cause internal wear. Additionally, maintaining cleaning protocols is vital for preventing dust accumulation and ensuring optimal airflow. Proper adherence to maintenance strategies can significantly extend the lifespan of your equipment. Ensuring that airflow is unobstructed by regularly inspecting and clearing vents helps prevent blockages that restrict airflow. Implementing routine filter inspection can also help catch issues early before they lead to equipment failure. Maintaining clean air filters and vents helps extend equipment lifespan and reduces the risk of unexpected breakdowns. Make this a routine part of your maintenance schedule to keep your machinery running at peak efficiency.

Check Hydraulic Systems and Fluid Levels

Regularly checking your hydraulic systems and fluid levels is essential for maintaining peak machinery performance. Low fluid levels can lead to decreased hydraulic pressure, reducing efficiency. Also, monitor for fluid contamination, which can cause system damage. Use the following table to guide your inspection:

| Checkpoint | Action |

|---|---|

| Hydraulic pressure | Ensure pressure is within recommended range. |

| Fluid levels | Top up if below the manufacturer’s mark. |

| Fluid contamination | Look for discoloration or debris. |

| Hydraulic hoses and fittings | Inspect for leaks or damage. |

Maintaining proper fluid levels and cleanliness prevents costly repairs and guarantees your machinery runs smoothly. Regular checks promote safety and extend equipment lifespan. Additionally, inspecting hydraulic hoses and fittings regularly can prevent leaks that might lead to system failure. Incorporating filter maintenance into your routine can further enhance system longevity and performance. Proper fluid filtration is crucial for avoiding contamination and maintaining system integrity. Implementing routine system diagnostics can help identify potential issues early and prevent unexpected breakdowns.

Lubricate Moving Parts and Joints

After inspecting your hydraulic systems and fluid levels, it’s time to focus on lubricating moving parts and joints. Consistent lubrication schedules are essential to keep machinery running smoothly and prevent wear. Regularly apply the appropriate lubricants to hinges, bearings,, and pivot points, ensuring each joint receives proper attention. Proper joint maintenance reduces friction and minimizes the risk of breakdowns. Use clean tools and avoid over-lubricating, as excess grease can attract dirt and debris. Check manufacturer recommendations for specific lubrication types and intervals. By maintaining well-lubricated moving parts and joints, you extend equipment lifespan and improve overall efficiency. Incorporating proper maintenance practices into your routine helps keep machinery operating reliably throughout the season.

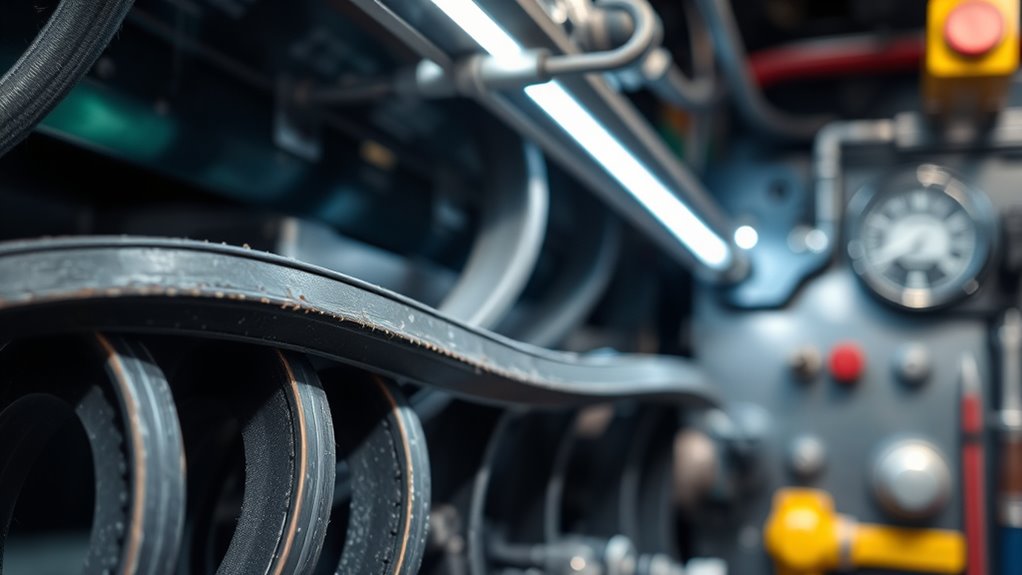

Examine Belts, Hoses, and Connections for Wear

Have you checked your belts, hoses, and connections recently? Inspecting these components is essential for smooth operation. Look for signs of wear, cracks, or fraying on belts, and ensure proper belt tension to prevent slipping. Check hoses for leaks, bulges, or brittleness, confirming hose integrity. Tighten loose connections and replace damaged parts promptly. Here’s a quick overview:

| Component | Common Issues | Action Needed |

|---|---|---|

| Belts | Cracks, fraying, slack | Adjust tension, replace |

| Hoses | Leaks, cracks, bulges | Repair or replace |

| Connections | Looseness, corrosion | Tighten or clean |

Regularly examining these elements helps prevent unexpected breakdowns and keeps your machinery running efficiently. Prioritize belt tension and hose integrity to avoid costly repairs down the line. Additionally, understanding the importance of GMC tuning can help optimize the performance and longevity of your vehicle. Proper maintenance of these parts is also supported by knowledge of sound healing science, which highlights how vibrations and frequencies can influence overall health and machinery function. Being aware of AI security vulnerabilities can also inform better safety protocols for automated systems involved in machinery operation. Recognizing the signs of fatigue in machinery can help prevent failures before they occur.

Test Safety Features and Emergency Stops

You should now verify that all safety features are functioning correctly and perform emergency stop tests to guarantee quick shutdowns if needed. Document your maintenance activities carefully, including any issues you find or resolve. Regularly checking these systems keeps everyone safe and helps maintain compliance. Utilizing hydrocolloid technology in safety equipment can enhance protection by providing a barrier against contaminants. Additionally, incorporating regular safety inspections into your schedule ensures ongoing effectiveness of safety measures. Furthermore, refer to support hours to ensure you have assistance available if technical issues arise during your maintenance procedures. Implementing waterpark safety standards can further improve overall safety performance. Consistently reviewing safety protocols is essential for adapting to new safety challenges and maintaining a secure environment.

Safety Feature Checks

Are safety features and emergency stops functioning correctly? You need to verify that all safety devices respond properly. First, perform hazard assessments to identify potential risks and ensure safety systems are appropriate. Second, test lockout procedures to confirm that equipment can be safely disabled during maintenance. Third, activate emergency stops to verify they immediately halt machinery operation. Make sure safety guards and sensors trigger as intended, and document any issues. Regular checks prevent malfunctions and ensure compliance. Clear communication with your team about safety feature status is essential. Additionally, understanding safety system components helps in troubleshooting and maintenance. Familiarity with Gold IRA options can also inform decisions about investment safety and security measures. Incorporating reliable safety devices enhances overall workplace safety. Regular testing of emergency stop systems is crucial for quick response during emergencies. By staying vigilant, you minimize risks and maintain a safe work environment. Remember, thorough testing now saves time and prevents accidents later.

Emergency Stop Testing

Testing emergency stops is a crucial step in verifying that safety features function correctly. During emergency stop testing, you should activate each emergency stop to ensure they immediately halt machinery and cut power. This confirms the safety protocol verification process is effective and that all emergency stops respond reliably under different conditions. Check that alarms activate simultaneously with the stop function and that reset procedures work smoothly. Document the response times and any issues encountered for future reference. Regular emergency stop testing helps prevent accidents by ensuring safety features are operational when needed most. Remember, prompt identification and resolution of any malfunctions can save lives and protect equipment, making this a vital part of your machinery maintenance schedule.

Maintenance Record Documentation

Maintaining accurate records of safety feature tests and emergency stop procedures is essential for effective machinery management. Proper maintenance record documentation guarantees you can track compliance and quickly identify issues. To keep records reliable, follow these steps:

- Regularly perform record accuracy checks to verify all entries are correct and complete.

- Document each safety feature test and emergency stop procedure immediately after completion.

- Review and update records periodically to reflect recent tests, repairs, or adjustments.

Review and Update Maintenance Records

You should verify that your maintenance records are accurate and current to guarantee reliable data. Updating documentation regularly helps track ongoing issues and identifies patterns over time. Reviewing historical maintenance trends allows you to make informed decisions for future upkeep.

Record Accuracy Checks

To guarantee the accuracy of maintenance records, it’s essential to regularly review and update them. Start by verifying sensor calibration data to ensure readings are precise and reliable. Next, perform record verification by cross-checking logs against actual maintenance activities to catch discrepancies. Finally, update any outdated information to reflect recent work, noting equipment conditions and repairs completed. This process helps identify errors early, prevents misdiagnoses, and maintains data integrity. Regularly scheduled record accuracy checks also streamline future maintenance tasks and improve equipment reliability. By staying diligent, you confirm your records remain a trustworthy resource, supporting efficient and effective machinery management.

Document Update Procedures

Regularly reviewing and updating maintenance records is crucial for guaranteeing their accuracy and usefulness. To streamline this process, integrate software systems that automatically sync data from your maintenance activities. This reduces manual entry errors and keeps records current. When updating documents, ensure your team follows clear procedures, leveraging training programs to reinforce proper documentation habits. Incorporate software integration to facilitate real-time updates, making maintenance history readily accessible for troubleshooting and planning. Regular audits of records help catch discrepancies early and maintain consistency. By establishing a routine review schedule, you guarantee that all maintenance activities are accurately documented, supporting compliance and operational efficiency. Clear documentation procedures, combined with ongoing training, keep your records reliable and your machinery running smoothly.

Historical Maintenance Trends

Analyzing maintenance records over time reveals valuable patterns that can improve machinery performance. By reviewing historical reliability data, you can identify which equipment consistently performs well and which requires extra attention. Tracking maintenance cost trends helps you allocate budgets more effectively. To harness these insights:

- Examine recurring failures to pinpoint weak points and improve reliability.

- Review repair and replacement costs to forecast future budgets and reduce expenses.

- Correlate downtime with maintenance activities to optimize scheduling and minimize production delays.

Schedule Professional Inspections and Servicing

When should you schedule professional inspections and servicing to keep your machinery running smoothly? Timing is key. Regular inspections help identify issues early, preventing costly breakdowns. Focus on equipment calibration to ensure precision and efficiency. Incorporate downtime analysis to determine when machinery is least active, minimizing production disruptions. Scheduling these services during planned downtime allows technicians to thoroughly evaluate systems and perform necessary repairs or adjustments. Don’t wait until performance declines; proactive maintenance extends equipment lifespan and maintains safety standards. Establish a routine that aligns with your operational schedule, ideally quarterly or semi-annually. By prioritizing professional inspections now, you can catch potential problems early, optimize equipment performance, and avoid unexpected shutdowns later.

Prepare Machinery for Seasonal Changes

Preparing your machinery for seasonal changes guarantees it operates efficiently throughout the year. To assure seasonal equipment readiness, start by inspecting all machinery for signs of wear or damage caused by previous seasons. Next, focus on machinery calibration to maintain accuracy and performance. Finally, implement preventive measures such as replacing worn parts and applying protective lubricants.

Here’s what you should do:

- Conduct a thorough inspection of all equipment, checking for corrosion or damage.

- Perform machinery calibration to guarantee precision during peak seasons.

- Prepare protective measures, like lubrication and sealing, to guard against environmental stressors.

These steps help you adapt your machinery to changing conditions, reducing downtime and extending equipment lifespan. Proper preparation ensures smooth operations and ideal productivity year-round.

Frequently Asked Questions

How Often Should Air Filters Be Replaced During Mid‑August?

You should replace air filters based on your equipment’s maintenance schedule, typically every 1 to 3 months. During mid‑August, check your filters for dirt and debris; if they’re dirty, it’s time for an air filter replacement. Regular maintenance keeps your machinery running smoothly and efficiently. Remember, sticking to your maintenance schedule guarantees peak performance and prevents costly repairs down the line.

What Are Signs of Hydraulic System Failure to Watch For?

They say a stitch in time saves nine, and spotting hydraulic system failure is no different. You should watch for signs like hydraulic fluid leaks and pressure fluctuations. Leaks can cause system damage, while pressure drops or surges indicate internal issues. Stay vigilant, inspect hoses and connections regularly, and address problems early to prevent costly repairs down the line. Your proactive approach keeps machinery running smoothly.

Which Lubricants Are Recommended for Different Machinery Parts?

You should choose lubricant types based on each machinery part’s needs to guarantee ideal performance. For example, use gear oil for gears, hydraulic oil for hydraulic systems, and grease for bearings. Proper lubrication reduces wear and tear, prevents overheating, and improves machinery performance. Always follow manufacturer recommendations for lubricant types and viscosity to keep your equipment running smoothly and extend its lifespan.

How Can I Identify Early Belt or Hose Wear?

To identify early belt or hose wear, you should start with regular visual inspections for cracks, fraying, or soft spots. Additionally, use vibration analysis to detect unusual vibrations that indicate potential issues. Pay close attention to any signs of slipping, looseness, or leaks. Combining these methods helps catch problems early, preventing costly breakdowns and ensuring your machinery runs smoothly and efficiently.

What Safety Features Require Testing Before Machinery Use?

Ever wonder why safety features need testing before machinery use? You should perform a thorough safety inspection to guarantee all safety devices, like emergency stops and guards, function correctly. Test emergency protocols to confirm quick response times. These checks help prevent accidents and protect everyone. Don’t skip this step—it’s essential for safe operation and compliance with safety standards, giving you peace of mind during machinery use.

Conclusion

By following this mid-August maintenance schedule, you keep your machinery running smoothly, like a well-oiled engine ready to roar. Picture yourself walking through gleaming equipment, vents clear, belts tight, and safety features standing guard. With each task completed, you’re not just maintaining machinery—you’re ensuring safe, reliable operation through every season’s shift. Stay proactive, and watch your equipment perform flawlessly, like a finely tuned machine ready to meet any challenge head-on.